Chilling Out With SpanTrack

As we have mentioned in previous blog entries, space is at a premium in 2013. For most distributors, expanding their product line must be accomplished without adding more warehouse space. This is especially true for companies who deal in products that need to be kept cool before they are shipped. Freezer and cooler space in a distribution center presents a unique challenge for distributors. The premium cost of freezer and cooler construction, coupled with the cost of maintaining appropriate temperatures, forces companies to look to increase pick facings without building more freezer or cooler facilities in their distribution center. Facilitating every product their customers need at thirty degrees below zero can make or break a distribution center. When NOW Natural Foods faced this challenge, they turned to Unex to provide the needed solutions.

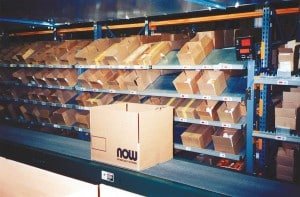

NOW Natural Foods provides a wide range of vitamins, herbs, supplements, and grocery products. They were looking to outfit their 100,000 square foot warehouse with the tools that would allow them to pick from their 1,400 SKU inventory in order to quickly pick and ship orders to their millions of customers. NOW's inventory combines drug, grocery, and department store products in order to provide a one-of-a-kind product line to its customers. NOW's varied product line includes items that must be kept in freezers before being shipped. They were in need of a system that made storing and picking freezer items as easy and convenient as picking items from their regular pallet rack.

After visiting Unex's plant and seeing SpanTrack at work, management at NOW decided that Unex's product line offered the best solutions to meet their order picking needs. The product was durable enough to meet their needs throughout their warehouse. It also presented a unique advantage that many other material handling products do not- its bearing-less roller design. These rollers do not require grease to reach their maximum functionality, and are designed for low temperature applications up to thirty degrees below zero. NOW's management saw a product that could drop into their existing freezer or pallet structures with ease, completely eliminating the need to expand the freezer facilities in their warehouse. This drop in design dramatically reduced the man hours required to install this product as well, further reducing the financial impact of implementing a Unex-provided system. SpanTrack also made it simple for NOW to implement a first in, first out stocking system. This advantage was absolutely crucial to NOW Natural Foods, as their entire product line is time-sensitive and labelled with expiration dates.

NOW Natural Foods is now equipped with an order picking system that is a hit with both management and employees. By integrating SpanTrack with a pick-to-light system, NOW's employees have sped up their picking pace while reducing effort per pick. An easier, faster pick means happier employees, and that means even happier customers. If you're looking to expand your cold product line, Unex can provide the tools needed to increase your freezer or cooler space without building additional freezer facilities. Our products can utilize your existing pallet structure in order to provide a faster, more durable solution for your order picking needs- even at sub-zero temperatures.