How To Increase Storage Density with Pareto's Bay

When space gets tight in your warehouse or distribution center, you need to find unconventional answers to one of the most common questions in the industry: how can you turn wasted space into an opportunity to add value to your operation?

Let’s look at the distribution center or warehouse storage space savings you can achieve by simply optimizing existing space within your racks that you may be overlooking.

Fast movers typically represent a small portion of your inventory but make up a large majority of your orders. These SKUs will be picked up and sent off to the loading dock almost as fast as they can be stocked. Thus, these SKUs are best left on pallets.

While this is the ideal way to store your fast-moving SKUs, there is an opportunity to add even more SKUs in the same footprint by utilizing the space just above your floor-level pallet positions. We call this "Pareto's Bay" and it's based on the Pareto Principle.

Related Reading: Warehouse Space Optimization: Carton Flow For Fast Movers

What is the Pareto Principle?

The Pareto principle states that, for many scenarios, approximately 80% of the effects come from 20% of the causes. Originally suggested by management consultant Joseph Juran and named after the Italian economist, Vilfredo Pareto, this principle exemplifies the large disparity between effort and result. So how do you apply this to order picking?

When we apply the Pareto Principle to order picking, we examine picks, in the same manner, to determine that 80% of the throughput will come from 20% of the SKUs. These SKUs (the 20%) represent your fastest movers. The other 80% consists of both slow and medium-moving SKUs. Based on cost and storage density alone, your slowest-moving SKUs should be stored on basic static shelving or in a dynamic high-density storage system like SpeedCell. As for your medium movers, the ideal storage solution is a carton flow system like SpanTrack Lane or SpanTrack Wheel Bed. Because these medium movers represent the bulk of an operation's picks, determining where and how to store them is critical in ensuring you're getting the most out of your space. That's where Pareto's Bay comes in!

What is "Pareto's Bay?"

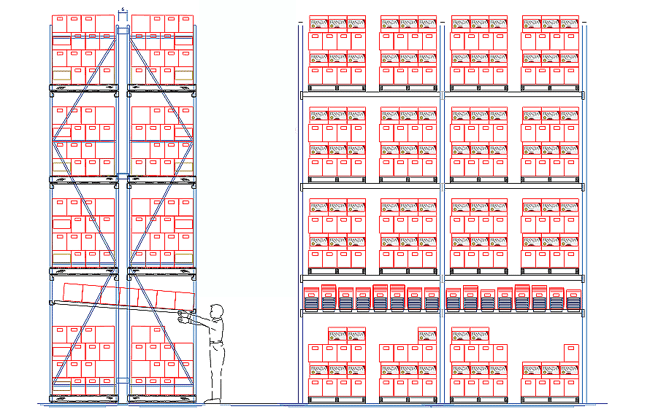

Pareto's Bay incorporates the 80/20 rule into the order picking process. The goal of Pareto's Bay is to combine both pallet storage and carton flow into one aisle that optimizes SKUs not only based on throughput, but also on frequency. In this scenario, workers are picking from pallets at floor level and each bay is 2 pallets wide. Right above these pallet positions, we add one level of carton flow. This adds 8 SKU positions above the 2 pallet-pick positions. Thus, we have created a Pareto's Bay with 2 fast-pick locations and 8 medium-pick locations all in the same bay. By implementing Pareto's Bay, travel time is reduced for order pickers - instead of just 2 SKUs, workers now have 10 SKUs to pick from.

Related Reading: The Pareto Principle Explained

By placing medium-moving products into carton flow positions within the Pareto’s Bay, you can eliminate pick facings further down the line and reduce the overall length of your pick paths.

In short, a Pareto's Bay will:

- Increase SKU density per bay by 500% on average.

- Cut your pick paths in half.

- Reduce the total square footage your operation requires.

Over time, decreases in the footprint of your operation and reduced pick times add up to thousands of dollars in savings in your warehouse or distribution center.

Related Reading: Want To Save On Pick Times? Start With Warehouse Storage

UNEX’s space optimization specialists can help you find and implement space-saving layouts like the Pareto’s Bay and cash in on the true storage potential of your operation. Get started by contacting our team today!