How to Maximize Space for Peak Season with High-Density Storage

The year-end shopping season isn’t just busy for retailers. It’s when fulfillment centers face their biggest test of space, speed, and efficiency. According to the National Retail Federation, the November–December period accounts for nearly one-fifth of all annual retail sales. In some categories, such as toys and hobbies, that share climbs past 25%.

Thriving in this make-or-break season isn’t just a question of nailing the perfect promotions. More often, it’s about execution in the warehouse. During the 2024 holiday peak, 58% of supply chain leaders said they failed to meet delivery or order accuracy goals. Those kinds of misses can quickly turn the dream of a holiday boom into a nightmare of customer complaints, returns, and lost revenue.

For many operations, those struggles begin long before the rush even starts. As inbound shipments pile up and SKU counts spike, facilities run short on space, and efficiency grinds down. But the real limiting factor isn’t space, it’s sprawling storage design that leaves too much space unused. High-density storage systems let operators reclaim wasted cubic footage, streamline picking, and keep operations moving at peak efficiency through the holidays and beyond.

Why Holiday Demand Pushes Storage to Its Limits

Warehouses must prepare for the holiday deluge long before the orders begin flooding in. In many cases, that means months of overcrowded shelves and space constraints. According to Prologis Research, warehouse utilization often climbs above 86% on average during peak periods, pushing many operations past the 85% efficiency threshold where congestion and slowdowns start to multiply. With inbound shipments stacking up and new seasonal SKUs arriving daily, even well-organized facilities can feel the strain.

That pressure is intensified by the fact that the shelves aren’t merely filling up with more of the same. Seasonal products, promotional bundles, and limited-edition variations expand SKU counts well past normal levels, while turnaround times shrink. At the same time, warehouses often rely on temporary labor to meet demand, bringing on workers who aren’t yet familiar with the layout or picking processes. Without clear organization, small inefficiencies quickly compound into lost productivity.

Expanding the building just for the holidays isn’t a realistic solution, especially with rising lease rates and construction costs. Instead, the smartest operators focus on optimizing the space they already have. That means tightening layouts, improving workflows, and adopting high-density storage solutions that set them up to store more SKUs in less space.

A Storage and Picking Strategy That Pays Off When Demand Peaks

Meeting peak demand starts with rethinking your existing use of space. Static shelving in pallet racking creates wide aisles, wasted vertical clearance, and static layouts that can’t flex with changing inventory needs. High-density storage systems solve this problem by compressing inventory into more efficient configurations that make use of every cubic inch without expanding a facility’s footprint.

Meeting peak demand starts with rethinking your existing use of space. Static shelving in pallet racking creates wide aisles, wasted vertical clearance, and static layouts that can’t flex with changing inventory needs. High-density storage systems solve this problem by compressing inventory into more efficient configurations that make use of every cubic inch without expanding a facility’s footprint.

Many fulfillment centers are already making this shift. The global market for high-density storage systems was valued at $10.5 billion in 2024 and is projected to grow nearly 9% annually through 2033, according to Verified Market Reports. It’s clear that more operators are investing in space-efficient systems that can readily adapt to SKU variability and unpredictable peaks.

They’re getting clear payoffs in return for that investment. High-density storage brings SKUs closer to pickers, reduces walking and reaching, and eliminates the dead zones caused by fixed shelving and excess aisle space. Their modular design also supports re-slotting and SKU consolidation, allowing product assortments to adjust quickly without reconfiguring entire bays.

In other words, high-density storage turns static space into a flexible, high-performance asset that adapts with demand instead of working against it. It’s a perfect fit for navigating seasonal surges.

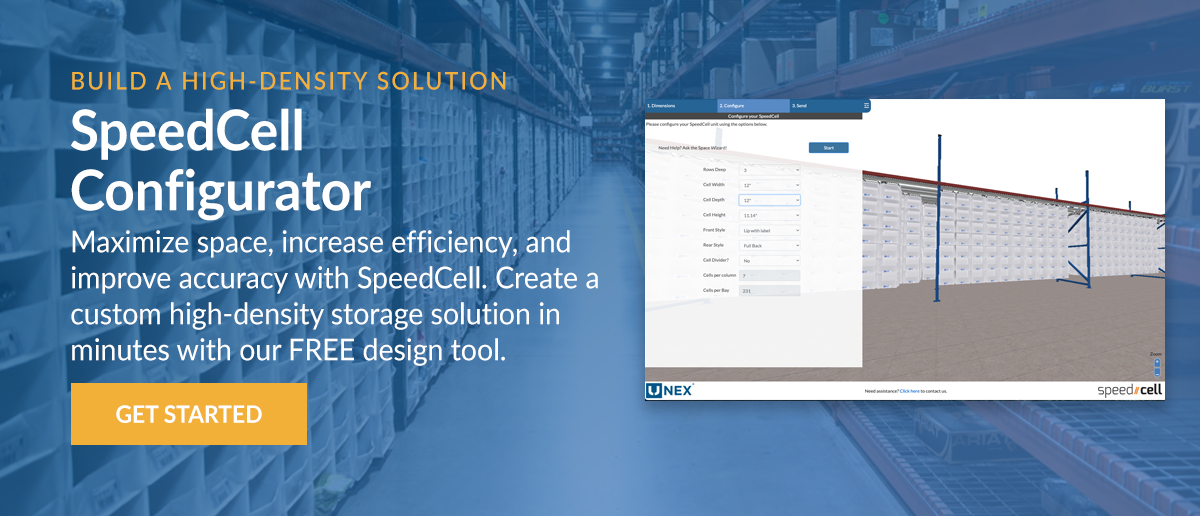

Discover a high-density storage solution and get the Ultimate Order Fulfillment Checklist! Download the Meet SpeedCell Guide.

Smarter Storage Solutions for the Busy Season

That type of adaptability is exactly what today’s warehouse teams need when the holidays hit. And UNEX delivers it with modular systems designed to work hand-in-hand. SpeedCell provides high-density storage to expand capacity, and SpeedCartt helps teams speed up picking for faster fulfillment.

That type of adaptability is exactly what today’s warehouse teams need when the holidays hit. And UNEX delivers it with modular systems designed to work hand-in-hand. SpeedCell provides high-density storage to expand capacity, and SpeedCartt helps teams speed up picking for faster fulfillment.

SpeedCell is a high-density storage solution that uses compact, suspended columns of durable cells to turn unused cubic space into active, organized inventory. By compressing up to 200’ of static shelving into just 40’ of high-capacity cells, it brings SKUs closer to pickers and maximizes capacity within your existing footprint.

SpeedCartt extends those efficiencies into mobile picking, giving workers an organized, ergonomic system that moves where it’s needed to meet demand. It’s a warehouse picking cart designed to help workers move quickly between zones and handle multiple orders without backtracking or confusion.

Together, SpeedCell and SpeedCartt create a faster, more organized operation ready for the pressure of holiday throughput:

- Maximize capacity: SpeedCell lets you store 40–60% more SKUs within the same footprint, while SpeedCartt offers more mobile pick facings than standard utility carts to streamline the picking process in high-traffic zones.

- Accelerate picking: SpeedCell speeds up access by keeping high-volume SKUs stored closer to the pick face, reducing travel and search time. SpeedCartt takes that a step further, enabling pickers to pull multiple orders at once and move efficiently between zones.

- Improve organization: Modular designs simplify slotting for new or seasonal SKUs. All cells have their own label holder to keep every product organized.

- Boost throughput: High-density storage helps workers maintain a steady flow even as volumes rise and labor fluctuates. SpeedCartt is especially useful for picking multiple orders at once.

- Enhance ergonomics: Instead of sprawling (horizontally and vertically) across shelves and square footage, high-volume inventory is positioned within reach to lessen strain and fatigue.

- Tailored to fit your operation: SpeedCell is available in multiple sizes and column configurations to make the most of your vertical and horizontal space, while SpeedCartt comes in several layouts to match your picking process and seasonal order volumes.

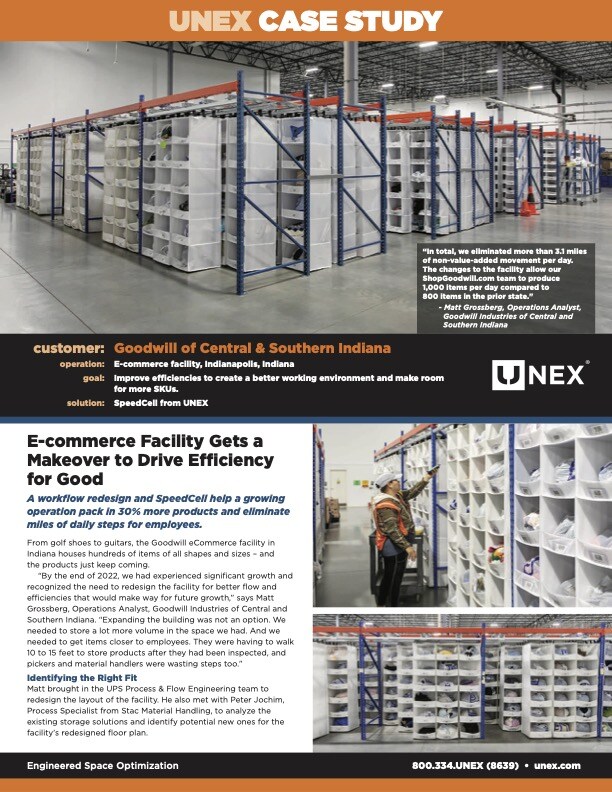

Goodwill’s High-Density Storage Makeover

These benefits aren’t theoretical. Real UNEX customers are reaping the rewards of these types of storage and picking solutions in peak season and beyond.

Consider Goodwill Industries of Central and Southern Indiana, which was running out of warehouse space in the face of rapid eCommerce growth. Shelves were stuffed with products of every shape and size, and employees were walking long distances just to stow or retrieve items. Expanding the building wasn’t an option, so the operations team focused on redesigning the layout for better space utilization and flow.

Working with Stac Material Handling, Goodwill analyzed its storage footprint and identified static shelving that left valuable cubic space unused. The team then turned to UNEX SpeedCell to convert that empty space into accessible, high-density storage.

Goodwill saw immediate results. By adding 1,806 SpeedCell locations across 13 bays, the company increased capacity by 30% while dramatically reducing the miles employees walked each day. Inventory was easier to locate and workflows became smoother, all without adding a single square foot of floor space.

Learn how SpeedCell helped Goodwill of Central & Southern Indiana boost efficiency and storage capacity. Download the Case Study.

Last-Minute Tips to Prepare for the Holiday Rush

Even if peak season is already underway, there’s still time to squeeze more efficiency out of your current setup. Small changes to layout, slotting, and flow can make a measurable difference in how quickly your team moves and how much product you can fit within your footprint.

Here are some simple steps you can take today to get the most from your space during the holidays:

- Re-slot strategically. Relocate fast movers to the most accessible pick zones and deploy modular systems to accommodate seasonal SKUs. Re-slotting ensures that high-velocity SKUs are positioned where pickers can access them with minimal effort. During peak, this can make or break throughput. Dynamic storage systems like SpeedCell make it easier to adapt slotting layouts quickly as SKU velocity shifts.

- Use mobile storage smartly. Deploy carts like SpeedCartt to bring high-volume items closer to pack-out areas and reduce walking during peak order periods. Deploying mobile carts such as SpeedCartt near packing or shipping zones helps absorb demand spikes without redesigning the whole layout. It’s especially useful for eCommerce peaks, where top-selling items change rapidly.

- Optimize travel paths. Map walking distances and remove wasted steps with better flow or mobile storage options. Even minor layout inefficiencies compound during peak season. Analyzing travel paths (often with WMS heatmaps or manual observation) helps eliminate backtracking and idle walking. Mobile storage or point-of-use replenishment reduces wasted motion and supports continuous flow.

- Tighten inventory control. Clear out obsolete or slow-moving stock to make room for higher-volume items. Freeing up space by removing obsolete or slow movers directly boosts efficiency and accuracy. It allows prime locations to be reserved for fast movers, reducing congestion and improving replenishment flow.

These quick wins can relieve the immediate strain of peak operations and highlight where more permanent improvements are needed.

Future-Proof Your Warehouse for the Next Peak

Once the holiday rush subsides, take what you’ve learned this season and use it to prepare early for the next one. The months after peak are the best time to assess where your layout, storage systems, and workflows fall short and make lasting changes before demand ramps up again.

- Audit your space. Measure utilization and pinpoint where static shelving limits throughput.

- Plan for scalability. Add systems like SpeedCell to fit more storage within the same footprint, ensuring you’re ready for next year’s volume.

- Test new workflows. Try re-slotting strategies or pilot modular storage zones in quieter months.

- Partner early. Working with a storage solutions provider now gives you time to design, install, and test updates long before next season begins.

Efficiency That Lasts Well Beyond the Holidays

Peak season might be temporary, but the gains from optimizing your space can last all year. High-density storage systems like SpeedCell and mobile picking carts like SpeedCartt help teams stay flexible, productive, and organized, whether during the busiest weeks of the year or the steady months that follow.

With the right combination of quick fixes today and strategic upgrades for tomorrow, you can turn the year’s busiest months into your biggest fulfillment wins. That momentum will carry you long after the holidays end. Contact UNEX today to future-proof your operations and stay ready for every season ahead.