Pick Replenishment: Why Back-to-Front is The Best Approach

Pick performance is one of the most important KPIs in any warehouse, especially as the number of SKUs stocked and handled skyrockets under e-commerce demands. Reducing time and motion while increasing the speed and accuracy of picks is key to optimizing operational productivity. In an environment where space is almost always a scarce resource, that can be a delicate balancing act.

That’s why one of the most cost-effective and productivity-enhancing fulfillment practices is back-to-front pick face replenishment via gravity carton flow racks.

Maximize Pick Performance with Back-to-Front Replenishment

Why is this approach so effective? It addresses a multitude of complex functional issues in a simple, straightforward manner. This method streamlines the replenishment process, tackling challenges such as inventory management, space optimization, and workflow efficiency, all of which are critical in a high-demand warehouse environment.

- Bulk to pick: Obviously, stock must be moved from its storage location to replenish pick stations. Having pickers travel to storage locations to replenish their station wastes considerable time and motion, and housing stock temporarily in waiting zones until it is needed wastes space and creates congestion. In contrast, back-to-front replenishment provides a planned, organized way to keep needed stock accessible.

- Pick efficiency: Pickers can’t pick stock that’s not there. Back-to-front replenishment ensures that ample stock is on hand, properly arranged, and easily visible and accessible to meet the shift’s picking needs. What’s more, when product is loaded from back to front, picking activity is not interrupted, keeping pick speeds and volumes running like clockwork.

- FIFO: Replenishment from the back is ideal for first-in, first-out environments because top-off replacement flows from the feed side to the pick side, keeping inventory in proper circulation.

Simply put, carton flow rack systems are central to any distribution center, efficiently storing and organizing product until it’s ready to ship. Because inventory is replenished from the back without interrupting order picking in front, inventory flows smoothly and steadily, ready to meet demand. That makes carton flow systems the best approach for virtually every DC.

Get The Definitive Guide to Carton Flow Storage and The Ultimate Order Picking Checklist. Download the guide today!

Enhancing Picking Efficiency with Carton Flow Systems and Roller Racks

In addition to back-to-front pick replenishment, carton flow systems and roller racks play a crucial role in optimizing the picking process within a warehouse. These solutions are particularly effective in environments where space is limited, and efficiency is paramount.

Carton Flow Systems

Carton flow systems, such as UNEX SpanTrack, are engineered to maximize productivity by providing dynamic storage that ensures easy access to products. These systems utilize gravity to feed products forward in a "first-in, first-out" (FIFO) sequence, which is ideal for managing inventory that needs to be rotated regularly. SpanTrack features full-width roller lanes and universal wheel beds that offer superior flow and flexibility, allowing you to store products of various sizes and weights without the need for additional shelving or supports.

Carton flow systems, such as UNEX SpanTrack, are engineered to maximize productivity by providing dynamic storage that ensures easy access to products. These systems utilize gravity to feed products forward in a "first-in, first-out" (FIFO) sequence, which is ideal for managing inventory that needs to be rotated regularly. SpanTrack features full-width roller lanes and universal wheel beds that offer superior flow and flexibility, allowing you to store products of various sizes and weights without the need for additional shelving or supports.

By integrating SpanTrack into your existing racks, you can increase the number of pick faces, reduce the time pickers spend searching for inventory, and minimize motion waste. This not only speeds up the picking process but also increases accuracy, helping to maintain a smooth flow of operations even during peak demand periods.

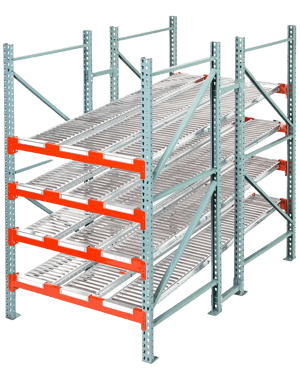

Roller Racks

UNEX Roller Racks are specifically designed to support high-density storage and efficient picking in environments where durability and easy accessibility are crucial. Roller Racks are a more standardized yet robust option for handling a wide range of products, particularly those that require consistent and reliable flow.

UNEX Roller Racks are specifically designed to support high-density storage and efficient picking in environments where durability and easy accessibility are crucial. Roller Racks are a more standardized yet robust option for handling a wide range of products, particularly those that require consistent and reliable flow.

Roller Racks are ideal for applications where high throughput and minimal downtime are essential. The racks are constructed with heavy-duty rollers that can withstand the rigors of continuous use in a busy warehouse environment. They allow for smooth, consistent movement of products, which is critical for maintaining the speed and efficiency of your picking operations. By facilitating easier access to stored items, Roller Racks help to streamline the workflow, reduce picker fatigue, and ensure that your operations run smoothly with minimal interruptions.

Optimize Your Picking Operations Today

Integrating UNEX Carton Flow systems and Roller Racks into your warehouse operations can significantly enhance pick efficiency, optimize space utilization, and improve overall productivity. Whether you’re dealing with high SKU counts, space constraints, or the need for rapid replenishment, these solutions provide the flexibility and durability required to meet the evolving demands of modern distribution centers. Contact us today or more information on how UNEX can help streamline your picking operations.