Building Ergonomic Industrial Workstations to Reduce Worker Stress and Fatigue

Key Takeaways

- Ergonomic industrial workstations help reduce worker fatigue, prevent injuries, and improve overall productivity in manufacturing environments.

- Poorly designed work areas contribute to strain, inefficiency, and high turnover, making ergonomic layout a critical operational priority.

- UNEX FlowCell industrial workstations improve ergonomics, increase space utilization by up to 50%, and boost productivity by up to 30%.

Today’s manufacturing landscape is full of technological leaps and global competition. The challenges manufacturers face are more complex than ever before. As automation, precision engineering, and digitalization increase, the pressure to deliver high-quality products swiftly has intensified, placing a significant burden on industrial workers. Creating ergonomic industrial workstations has become crucial to ensure the workforce’s well-being and maintain operational efficiency.

Currently, the manufacturing sector is a dynamic ecosystem of innovation and efficiency, driven by a relentless pursuit of productivity gains and cost-effectiveness. Advanced technologies such as robotics, artificial intelligence, Industry 4.0, and the Internet of Things (IoT) are driving a new era of manufacturing capabilities. While these advancements offer unprecedented opportunities, they also introduce challenges that demand a strategic approach to workforce management and workplace design.

Manufacturing Industry Challenges

Before we dive into building ergonomic industrial workstations, it’s helpful to understand the current challenges the manufacturing industry is facing. The issues below are not new, but as global demand increases, businesses must continually improve operational efficiency to combat these challenges.

- Technological Evolution: Integrating cutting-edge technologies has led to an increasingly complex manufacturing process. Workers must adapt swiftly to evolving tools and systems, straining their cognitive and physical capacities. According to a report, 54% of manufacturers expect to significantly increase their investment in technology in 2024, showing the profound impact of technological evolution on the industry.

- Tight Production Schedules: Global markets demand quicker product turnaround times, compelling manufacturers to streamline production schedules. The need for rapid output can lead to extended working hours and increased pressure on workers to meet demanding deadlines. A recent study reports that 70.13% of manufacturing employees have considered leaving due to burnout.

- Skills Gap and Workforce Challenges: The shift towards digitalization and automation requires a skilled and adaptable workforce. However, the industry is grappling with a growing skills gap, making finding and retaining qualified workers challenging. A survey conducted by The Manufacturing Institute reveals that over 2.1 million manufacturing jobs may go unfilled by 2030 due to the skills gap and not having enough skilled workers in the workforce.

Let’s examine how these challenges affect worker stress and fatigue and discuss how strategically incorporating ergonomic industrial workstations can mitigate these pressures.

What Are Industrial Workstations?

Industrial workstations are specialized workbenches or equipment within manufacturing facilities designed to optimize efficiency, enhance productivity, and prioritize the well-being of workers. These workstations encompass the physical space, equipment, and tools necessary for employees to perform their tasks seamlessly. Regarding ergonomics, industrial workstations focus on creating environments that reduce physical strain, eliminate repetitive stress injuries, and promote overall worker comfort.

Benefits of Industrial Workstations

- Ergonomic Design: Industrial workstations are crafted with ergonomic principles at the forefront. This involves tailoring the workstation layout and equipment to match the natural movements and capabilities of the human body. By minimizing awkward postures, reducing muscle strain, and mitigating the risk of musculoskeletal disorders, ergonomic design can work wonders.

- Increased Productivity: Well-designed workstations increase productivity by optimizing the workflow and reducing unnecessary movements. Ergonomically arranged tools and equipment enable workers to perform tasks more efficiently, leading to a more streamlined production process.

- Worker Well-being: By minimizing physical strain, industrial workstations contribute to a healthier, more satisfied workforce, reducing the likelihood of fatigue, absenteeism, and workplace injuries.

Boosting Ergonomics with FlowCell Industrial Workstations

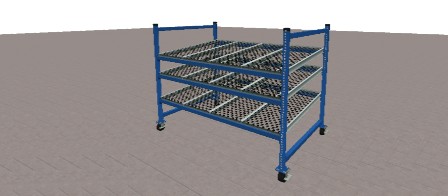

UNEX FlowCell offers flexibility and enhanced ergonomics, aligning seamlessly with Lean principles to enhance manufacturing operations. FlowCell industrial workstations organize inventory, accelerate pick productivity, and eliminate waste. Key ergonomic benefits of UNEX FlowCell industrial workstations include:

- Minimize reaching and improve ergonomics by reducing injury and fatigue

- Keep the factory floor organized — totes and boxes can be stored in return lanes rather than on the floor

- Clean, organized sightlines

- Engineered to angle parts toward workers for a more ergonomic pick

FlowCell workstations take advantage of simple physics to improve operator ergonomics significantly. Gravity-powered conveyor systems minimize reaching, bending, lifting, and carrying, allowing workers to increase their pick and production speed while reducing fatigue and inefficient or wasted movements. FlowCell industrial workstations flow products forward, saving workers valuable time and energy wasted searching and retrieving materials stored out of reach in the back of static systems.

Boost Productivity with FlowCell

Enhancing Efficiency with FlowCell Industrial Workstations

When it comes to FlowCell industrial workstations, ergonomics and efficiency go hand in hand. FlowCell not only improves ergonomics, it also increases space utilization by up to 50% and boosts production efficiency by up to 30%.

UNEX modular flow-through workstations utilize SpanTrack carton flow tracks and are ideal for various assembly, manufacturing, and warehousing applications. Parts can be "mixed and matched" to create your perfect solution. Rugged and durable, FlowCell is constructed of heavy gauge steel. This long-lasting solution also increases space utilization by up to 50% and is proven to boost productivity by up to 30%. Achieving peak organization and space savings in an industrial environment is possible with our fully customizable FlowCell industrial workstations.

UNEX builds engineered-to-order industrial workstations that support productivity even in the harshest and most demanding industrial environments. With a cell capacity of 1,000 lbs per level at 8' wide and 3,000 lbs total load with casters, plus a track capacity of up to 100 lbs per ft., FlowCell is one of the most rugged and durable solutions on the market. Our ergonomic workbenches allow workers to remain organized and efficient when assembling, kitting, packing, or testing. Accessories like add-on trays and overhead toolbars provide even more options for designing a solution that will meet your facility's needs.

Connect with UNEX Industrial Workstation Experts

If you’re looking to create ergonomic industrial workstations, our team of experts can work with our distributor partners local to your area to develop a complete solution for your business. Our combined years of experience with partners across the country will help you design ergonomic industrial workstations to meet your needs. Plus, we offer free engineering support on all our projects to ensure your UNEX solutions are tailored specifically to your unique situation. Contact us today to get started on your next project!