Integrating Dynamic High-Density Storage Systems into Your Warehouse Plan

Efficient warehouse storage solutions are a critical component of supply chain management, playing a pivotal role in ensuring the smooth flow of goods from manufacturers to consumers. Improving warehouse storage efficiency can create the flexibility needed to expand operations with demand, maximizing space while boosting productivity thanks to reduced travel times and lowered costs.

The Importance of Efficient Warehouse Storage

Warehouse storage solutions directly impact the order fulfillment process's speed, accuracy, and cost-effectiveness. An efficiently designed storage system ensures organized inventory, minimizing the time required for picking and packing - accelerating the order fulfillment process, and helping businesses meet customer expectations for faster deliveries.

On the contrary, inefficient warehouse storage layouts can lead to delays, errors, and increased labor costs as workers struggle to locate and retrieve items to fulfill orders. Proper storage optimization enhances inventory visibility, decreasing mispicks and the likelihood of out-of-stocks or overstock. It enables companies to align storage capacity with demand fluctuations. Ultimately, warehouse optimization in supply chain management is integral to increasing productivity, minimizing costs, and delivering a seamless, timely, end-to-end customer experience.

Maximizing Space Utilization with Dynamic Industrial Shelving

A dynamic storage system is simple strategic warehouse equipment that prioritizes space utilization and reduces wasted space. Dynamic storage solutions utilize gravity or motion to move inventory in a warehouse. The most common examples of dynamic storage include carton flow, industrial shelving, and pallet flow.

SpeedCell, a dynamic industrial shelving solution, allows warehouse managers to turn under-utilized space into usable storage. This dynamic system integrates into pallet rack structures, creating high-density storage ideal for each picking operations. Implementing SpeedCell can boost storage density by as much as 60%, reducing travel time for workers and significantly impacting a warehouse's bottom line.

Take Overton's as one example. Rapid growth in the company's apparel category meant cube utilization had suffered, with improperly sized pick locations and growing wear and tear on their bin boxes. Worse yet, employees constantly had to climb ladders or get on their knees to reach the back of the bin boxes.

When order volumes expanded, Overton’s couldn’t keep up. Seeking to improve warehouse productivity, Overton's installed 112 SpeedCell bays, adding 219 locations in each bay and 17,000 locations in total.

The results?

- 30% Improved Efficiency

- 150% Increase in Pick Locations

- 1000s of SKU Locations Added

Since SpeedCell allows workers to pick products quickly, Overton's achieved greater efficiency with staff already on hand. Best of all, Overton's achieved this without expanding their warehouse footprint. The company gained significant cost savings by delaying site alterations they previously saw as inevitable.

Learn how Overton's avoided costly warehouse renovations by implementing SpeedCell. Download the Case Study.

Tailoring Your Shelving System to Your Needs

When planning your warehouse layout, assessing storage needs is crucial. Begin with a comprehensive analysis of your current inventory and future growth projections. Consider the product's dimensions and storage requirements, such as temperature sensitivity or fragility.

Assess your inventory turnover rate for optimal storage density and accessibility. Evaluate historical data on order frequency and volume to anticipate future demands accurately. Consider the efficiency of existing storage systems and identify any bottlenecks or inefficiencies. Interview your warehouse staff to gather insights into daily operations, challenges, and potential improvements. Don’t forget to consider industry trends and seasonal fluctuations impacting your storage requirements.

By conducting a thorough assessment that considers both current conditions and future expectations, you can tailor your dynamic industrial shelving system to meet present demands while allowing for scalability and flexibility.

Enhancing Picking Efficiency and Inventory Management

Picking efficiency is crucial in meeting customer demands for fast and reliable deliveries. Dynamic industrial shelving systems, like UNEX SpeedCell, create a highly organized condensed storage space and enable easy product access, reducing the time and effort required to locate and retrieve items. An organized warehouse allows for better inventory control and quicker, more accurate order fulfillment. With efficient warehouse storage solutions, businesses can implement robust inventory management practices, like regular audits, WMS, and real-time tracking systems.

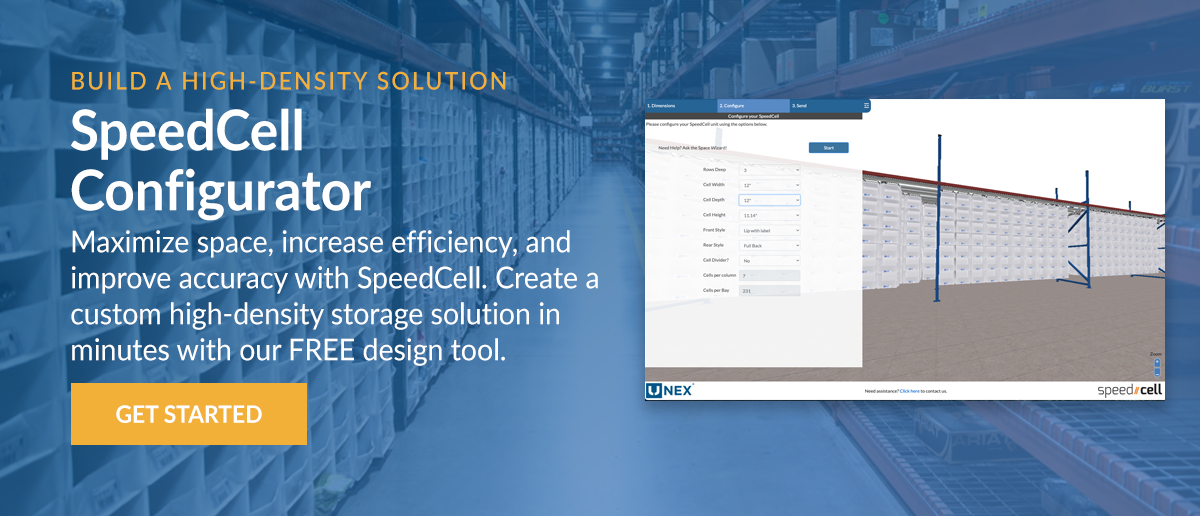

See How SpeedCell Can Improve Your Warehouse

UNEX SpeedCell can help reduce costs by minimizing the space required to store products, lowering inventory shrinkage, and decreasing labor costs. SpeedCell boosts productivity by reducing travel time and time spent searching for products. The ergonomic design can also help reduce the risk of injury or overexertion, leading to lost time and productivity. SpeedCell delivers a highly efficient, more accurate pick, improving customer satisfaction.

Maximize space utilization and improve picking efficiency in your operation when you implement a dynamic industrial shelving solution into your warehouse plan. UNEX offers warehouse optimization solutions tailored to your unique needs, including free engineering support for your SpeedCell project. Contact us today to explore the possibilities for your operation!