Conveyors

In today's fast-paced logistics and order fulfillment environments, efficient material handling is crucial for maintaining productivity and reducing operational costs. Manual transportation of goods can be time-consuming, labor-intensive, and prone to errors, leading to bottlenecks and decreased throughput. Gravity conveyors offer a reliable and cost-effective solution to keep your operations running smoothly.

Conveyors Increase Efficiency and Throughput

UNEX gravity conveyors and pallet flow systems keep items moving in an organized manner throughout your facility. UNEX conveyors are flexible, rugged, low-maintenance, and suitable for transporting multiple-sized boxes, cases, cartons, or totes. With a range of options, including multiple lengths, widths, and roller and wheel conveyor styles, UNEX conveyors seamlessly integrate into your existing infrastructure, streamlining processes and maximizing efficiency.

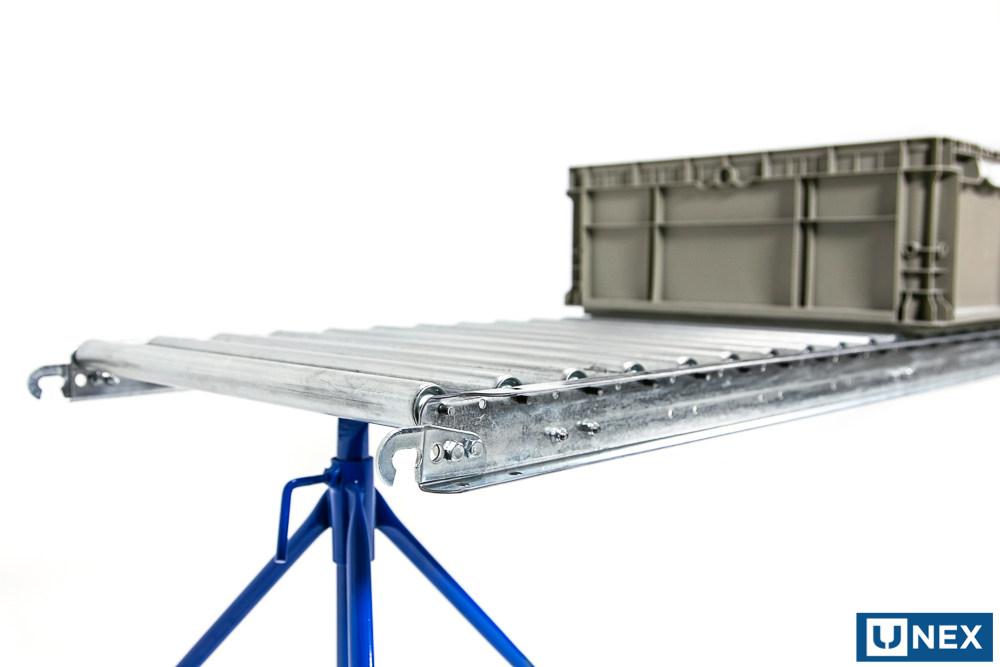

Gravity Conveyor

Durable, efficient gravity conveyors that come in multiple lengths and widths to move all types of loads.

Pallet Track

Durable pallet track rollers or wheel rails create a dynamic pallet flow system designed to optimize flow.

Connect with an Expert

Fill out the form below to request a consultation to find the ideal conveyor solution for your unique space.

Unlock Continuous Material Flow with Gravity Conveyors

Gravity conveyors are an ideal solution for operations that require continuous, uninterrupted material flow. Whether you need to transport products between workstations, move goods from receiving to storage areas, or streamline order fulfillment processes, gravity conveyors offer a reliable and efficient means of material handling.

These conveyor systems are well-suited for environments with high throughput requirements, such as distribution centers, manufacturing facilities, and eCommerce fulfillment operations. By eliminating the need for manual transportation, gravity conveyors reduce the risk of bottlenecks, allowing for a smooth and consistent flow of materials throughout your facility.

UNEX offers a durable and low-maintenance solution that can withstand the demands of your operation. UNEX conveyor systems will allow you to streamline processes, reduce labor costs, and enhance the overall efficiency of your facility.

How Gravity Conveyors Optimize Warehouse Operations

Warehouses and order fulfillment centers face constant pressures to improve efficiency, increase throughput, and reduce operational costs. Implementing gravity conveyors can address these challenges by streamlining material handling processes and minimizing manual labor. Here are some key benefits of incorporating gravity conveyors into your facility:

- Uninterrupted Product Flow: Gravity conveyors utilize the power of gravity to transport materials seamlessly, eliminating the need for manual pushing or pulling. This continuous, uninterrupted flow maximizes productivity and minimizes bottlenecks, ensuring smooth operations from receiving to shipping.

- Increased Throughput and Efficiency: By reducing the time and effort required for material transportation, gravity conveyors enable faster processing times and higher output rates. This increased efficiency translates into cost savings and improved customer satisfaction through quicker order fulfillment.

- Ergonomic and Safe Material Handling: Manual material handling methods can lead to injuries and fatigue, impacting productivity and driving up costs. Gravity conveyors minimize physical strain on workers, promoting a safer and more ergonomic work environment while reducing the risk of product damage.

- Flexibility and Customization: UNEX offers a wide range of gravity conveyor solutions, including straight runs, curves, and spurs, tailored to fit your unique facility layout and material handling requirements. This adaptability ensures seamless integration and optimized material flow throughout your operations.

FAQ

What is your lead time for Gravity Conveyor?

All UNEX products are engineered-to-order, and lead time depends on the size and complexity of your order. However, average lead times for Gravity Conveyor solutions range from 3 to 12 weeks.

When should I use a skatewheel conveyor?

Skatewheel Gravity Conveyor is ideally suited to convey lightweight packages, where operations require portable or temporary conveyor lines such as warehousing or shipping areas. Here are the top 3 reasons you may want to choose skatewheel conveyor for your application:

- Skatewheel conveyors require less pitch or angle to transport product.

- Empty boxes and very light loads travel better because the force required to start several wheels in motion is less than a full-width roller.

Product tracking is better on skatewheel conveyors, especially on curves, as the differential action of the individual wheels allows the product to maintain its original position on the conveyor.

Are there items that cannot be conveyed on a skatewheel conveyor?

Yes, containers with ring-banded bottoms, drums with chimes, most bagged items, and cartons with flimsy or soft bottoms cannot be handled on a skatewheel conveyor.

What are some examples of roller conveyor uses?

Gravity roller is an almost universal answer when it comes to handling products with a smooth, flat bottom. Gravity rollers can be used in flat (level) lines with the product being pushed manually or set at a decline, allowing the load to move forward by gravity. Gravity rollers are also well-suited for order picking applications – both for dynamic storage and the pick conveyor used along the front of the rack.

Can you provide a portable conveyor?

Yes, UNEX makes both skatewheel and 1 ⅜” diameter roller in an aluminum construction. The frames, wheels, or rollers are lightweight aluminum, making them easy to set up and takedown. Portable tripod supports are used to allow for quick setup – the conveyor cross members nest into the top of the support, and height adjustments require no tools. This makes them ideal for setting up temporary lines for loading dock applications.

Companies That Choose UNEX

George J. Falter

Capital Candy

Distributor Reduces Pickers by a Third, Maximizes Space and Efficiency with Roller Rack and Gravity Conveyor