What is High-Density Storage?

Definitions, Benefits, and Examples

High-density storage solutions are space-efficient systems designed to maximize the amount of material stored within a warehouse or retail storage space. These systems smartly use physical space to store more inventory within a smaller footprint without compromising access or efficiency. It’s not a single technology or method, but rather a category of storage systems designed to help warehouses, distribution centers, and production facilities manage more SKUs in less space.

Implementing high-density storage becomes essential when space is limited, SKU counts are increasing, and fulfillment expectations demand faster picking and better organization, all of which consistently impact operations across the supply chain.

Unlike static shelving that can create wasted space or “dead zones,” high-density storage compresses inventory into more efficient, easily accessible layouts that utilize 100% of the space. The result is a system that increases throughput, reduces picker travel time, and creates room for growth without adding square footage.

Where is High-Density Storage Used?

High-density storage systems are found wherever space efficiency and fast access to inventory are priorities. This includes:

- Order fulfillment warehouses and eCommerce fulfillment centers managing thousands of SKUs

- Third-party logistics providers (3PLs) looking to optimize space for multiple clients and ever-changing contracts

- Retail operations in need of optimizing space in already overloaded and disorganized backrooms

Every order fulfillment operation can benefit from high-density storage systems of some kind to house slower-moving SKUs, seasonal items, smaller items, or SKUs that still require dedicated storage but don't need to occupy more space than necessary.

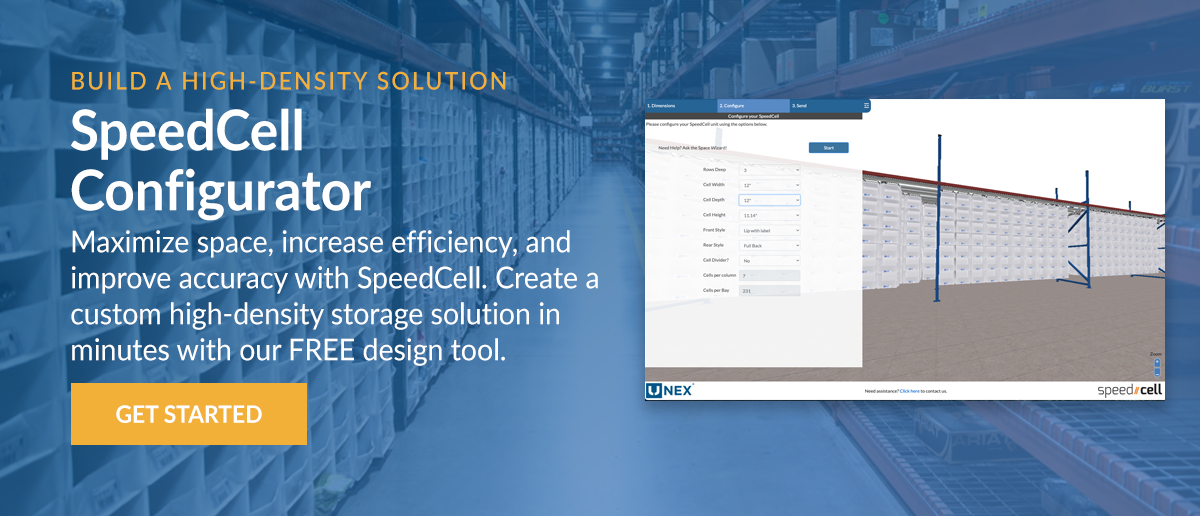

Discover a high-density storage solution and get the Ultimate Order Fulfillment Checklist! Download the Meet SpeedCell Guide.

Common Types of High-Density Storage Systems

No two operations are identical, and high-density storage is not a one-size-fits-all solution. Your operation may find a need for one or all of these systems to create the perfect order picking environment for your unique situation. These are some of the most common types of high-density storage systems on the market:

Automated Storage and Retrieval Systems (ASRS)

ASRS utilizes robotics and conveyors to retrieve inventory from high-density storage areas automatically. They're ideal for high-volume, high-velocity operations with the capital and throughput to justify automation.

Vertical Lift Modules (VLMs)

VLMs are enclosed systems that move trays of inventory vertically within a tower, delivering them to an access window at the operator's height. This makes efficient use of overhead space, improving security and ergonomics.

Modular Bin Shelving

These systems allow storage of small items or slow-moving SKUs in clearly defined compartments. They're often modular, scalable, and adaptable to SKU changes over time.

Dynamic High-Density Storage Systems

Cell or bin-based, mobile storage systems that condense inventory into sliding or layered compartments within standard pallet racking. These systems often strike a balance between cost-effectiveness, fast picking, and density.

Each of these solutions offers different strengths depending on operational needs, space constraints, and the types of inventory being stored.

What Problems Does High-Density Storage Solve?

For many operations, high-density storage addresses multiple pain points at once. It reduces the walking distance between picks, improves slotting accuracy, and organizes inventory in a way that supports faster fulfillment. When SKUs grow but space doesn’t, it offers a way to scale without relocating or investing in costly expansions.

High-density storage also improves safety and ergonomics by reducing the need to reach, bend, or climb to access inventory. For example, if you’re storing items on basic, flat industrial shelving, workers cannot reach all areas within the racks to stock or pick items. This creates dead zones of unused space, costing the operation valuable time and money. High-density storage systems eliminate this issue by maximizing space utilization. Plus, in labor-constrained environments (which most are these days), shortening pick paths and centralizing storage helps teams do more with fewer steps and fewer people.

These are just a few of the basic benefits of implementing high-density storage systems.

SpeedCell: A Smarter Take on High-Density Storage

SpeedCell is a high-density storage system engineered to fit into standard pallet racking. Instead of using static shelving or complex automation, it introduces a dynamic cell-based system that increases SKU density while keeping pick access simple and ergonomic.

SpeedCell is a high-density storage system engineered to fit into standard pallet racking. Instead of using static shelving or complex automation, it introduces a dynamic cell-based system that increases SKU density while keeping pick access simple and ergonomic.

Each bay of SpeedCell contains multiple columns of durable cells suspended from a track. These columns glide left and right, allowing workers to access rows of SKUs stored in the full depth of the rack. This space-efficient design will enable operations to store up to 60% more inventory in the same footprint while reducing labor costs by up to 40%.

Unlike automation-heavy systems, SpeedCell installs quickly, adapts to inventory changes, and requires no specialized training or infrastructure to get started. It’s ideal for each picking applications, SKU-dense storage zones, and any facility facing space constraints.

SpeedCell is commonly used in eCommerce and omnichannel order fulfillment warehouses, retail backrooms and order pickup areas, and 3PL facilities. As SKU counts grow and floor space remains at a premium, SpeedCell offers a practical, scalable solution that boosts productivity without the complexity of automated systems. Meaning you can quickly and easily prove your ROI and start reaping the benefits of this space-saving system immediately.

Who Can Benefit from SpeedCell High-Density Storage?

SpeedCell is ideal for each picking (also known as split-case picking) in warehousing, order fulfillment, and retail settings. This dynamic storage solution can be found in a variety of facilities that store a wide range of products. Some examples include:

- Apparel and Footwear

- Automotive Retail

- Cannabis

- Consumer Packaged Goods (CPGs)

- Convenience Retail

- Cosmetics

- Electronics

- Hardware

- Pharmaceuticals

- Toys and Hobbies

SpeedCell High-Density Storage Features and Benefits

- Offered in 6 standard column sizes ranging from XS to XXL

- Can be purchased with or without racking

- Ergonomically designed

- Operating temperature of -20° to 180°F (-29° to 82°C)

- Resistant to flame and mold

- Storage Capacity - cell: up to 35 lbs; column: up to 240 lbs

- 5-year warranty

Effective High-Density Storage is Within Reach

If you're running out of space or struggling with inventory accessibility, a high-density storage solution may be what you need. Whether you're reoptimizing your order picking operation, looking to increase SKU capacity, or simply trying to reduce labor waste, UNEX can help. Our team of experts will work with you to assess your current storage needs and design a tailor-made solution, like SpeedCell high-density storage, to solve today’s challenges and prepare you for what’s next. Contact UNEX today to get started on your high-density storage solution!