Dynamic High-Density Storage and the SpeedCell Advantage

In this article, we take a deep dive into the advantages of implementing a SpeedCell dynamic high-density storage system by comparing it to pallet rack with wire deck and static industrial shelving. We will compare each system and provide a detailed breakdown of the space and cost-saving benefits of SpeedCell.

Static vs. Dynamic High-Density Storage Systems

The best way to understand the benefits of implementing a dynamic high-density storage system like SpeedCell is by comparing it to pallet rack with wire deck and industrial static shelving. Taking the two most basic forms of static storage that are most commonly found in warehouses today and putting them up against the space-saving advantages of a dynamic high-density storage system like SpeedCell will allow you to fully visualize the benefits of converting your static storage into dynamic storage with SpeedCell.

The key benefits of converting static storage into dynamic storage:

- Increase space utilization by eliminating inaccessible areas or “dead zones.”

- Decrease pick paths (linear footage) to save time and money on labor and reduce mispicks.

- Reduce required warehouse storage space, saving on cost per square foot.

What is Industrial Shelving?

Industrial shelving is a type of storage solution commonly used in warehouses. There are many types of industrial shelving, but some of the more popular options include:

- Steel shelving (pallet rack, wide span racks)

- Rivet shelving

- Wire shelving

- Dynamic shelving

What is SpeedCell?

SpeedCell is a dynamic high-density storage system that consists of columns made of high-strength industrial textiles. These columns come in a variety of sizes and configurations. Designs can range from 1 to 3 rows deep, and up to 12 columns wide. SpeedCell columns are made up of 2 to 10 storage levels or “cells” per column. Each cell has a unique location label holder and is ergonomically designed to reduce the need for deep bending, stretching, or step stools. The back rows of a SpeedCell bay are accessed by simply sliding the front columns left or right, allowing step-in access to the next row.

Discover a high-density storage solution and get the Ultimate Order Fulfillment Checklist! Download the Meet SpeedCell Guide.

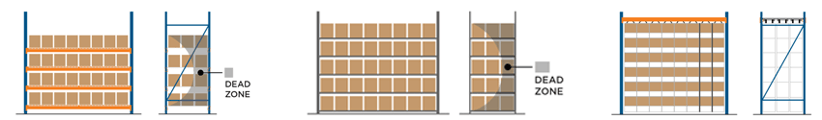

Eliminating Dead Zones with SpeedCell

The most obvious benefit of implementing a dynamic shelving system like SpeedCell comes in the form of utilizing and making accessible, every square inch of space within your racks. As you can see, the static storage position and fixed shelf heights of pallet rack with wire deck and industrial shelving limit the amount of space within the racks or shelves that can actually be used for SKU storage.

With the static storage mediums, only the front SKU positions in the very center are reached with ease. When storing products in this type of shelving, workers won’t be able to easily (or perhaps at all) push product to the back of the shelf without the need for a step ladder, or risky climbing, bending, and reaching motions. This is time waster #1. Even if workers can fully utilize these shelves by getting products all the way to the top, bottom, and back, pickers then have to climb, bend, and reach to retrieve these items. Thus, the dead zone is created.

With SpeedCell high-density storage, the dead zone is 100% eliminated. The back rows of a SpeedCell bay are accessed by easily sliding the front rows of columns left or right to access the back row(s), utilizing every square inch of the bay for SKU storage, and eliminating the need for deep bending or reaching to pick products. With SpeedCell, all rows are a front row.

Decreasing Pick Paths with SpeedCell

Possibly the most common standard setup in warehouses today, pallet racking with wire deck is a great starting point for many businesses, especially those just getting up and running. Likewise, industrial shelving is often a great solution for businesses that are rapidly expanding into new facilities or just looking to increase capacity in various areas around the warehouse. That said, these static shelving solutions can only take you so far, as they do not allow for maximum space utilization compared to SpeedCell.

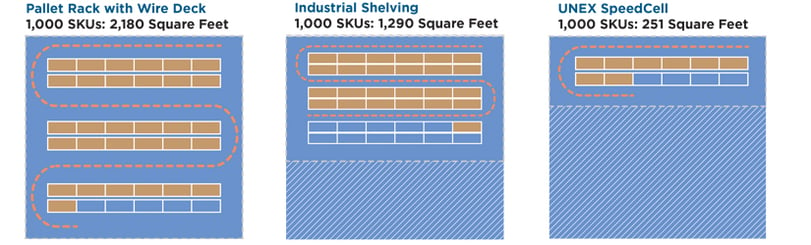

Comparing potential pick paths between the static shelving systems versus SpeedCell high-density storage can help visualize the space-saving advantages of converting static storage to dynamic.

Let’s examine 3 scenarios.

Storing 1,000 SKUs in pallet rack with wire deck:

Storing 1,000 SKUs in pallet rack with wire deck:

- 10’ aisles

- 8’ back-to-back rack

4 levels of wire deck with 8 slots across per level - Picking from open front boxes

- Requires 2,180 square feet of floor space to store 1,000 SKUs

Storing 1,000 SKUs in industrial shelving:

Storing 1,000 SKUs in industrial shelving:

- 4’ aisles

- 6’ back-to-back shelving

- 5 levels with 8 slots across per level

- Picking from open front boxes

- Requires 1,290 square feet of floor space to store 1,000 SKUs

Storing 1,000 SKUs in SpeedCell dynamic shelving:

Storing 1,000 SKUs in SpeedCell dynamic shelving:

- 8’ back-to-back rack

- 6 SpeedCells high

- 3 rows of SpeedCell deep with a 6/7/8 configuration of columns (6 SpeedCell columns in the first row, 7 in the second row, and 8 in the third)

- Requires 251 square feet of floor space to store 1,000 SKUs

A side-by-side comparison shows pick paths are significantly reduced when you make the jump from pallet rack with wire deck to SpeedCell. How does this translate to cost savings? Let’s examine the numbers:

- We based worker travel time on an average walking speed of 3 miles per hour

- We’re considering that these paths are traveled approximately 8 times per shift

- With 261 working days per year

- And a $35 per hour labor rate

Considering these industry average stats and taking this into account per worker, per 1,000 SKUs, the facility with SpeedCell saves $613 per picker per year!

Reducing Floor Space with SpeedCell

Using the same scenario - 3 facilities, one using pallet rack with wire deck, one with static industrial shelving, and one with SpeedCell - let’s review floor space utilization.

- Storing 1,000 SKUs in pallet rack with wire deck required 2,180 square feet of space.

- Storing 1,000 SKUs in static industrial shelving reduces the square footage used by about 40% from 2,180 square feet down to 1,290 square feet.

- Storing those same 1,000 SKUs in SpeedCell reduces the square footage used by 80% compared to static industrial shelving, and a whopping 88% compared to pallet rack with wire deck, taking the floor space used down to just 251 square feet.

To break it down, let’s say we’re working with a cost of $.50 per square foot per month. Over one year (12 months), the price per square foot looks like this:

- Pallet rack with wire deck - 2,180 square feet costs $13,080 per year

- Industrial shelving - 1,290 square feet costs $7,740 per year

- SpeedCell - 251 square feet costs $1,506 per year

So, to give you just a basic idea of how much can be saved by implementing SpeedCell, the facility with the pallet rack and wire deck costs over 8 times as much as the one with SpeedCell. This translates to over $11,500 saved on floor space per year when you convert your static pallet racking into dynamic shelving using SpeedCell. Imagine saving over 88% on your cost per square foot! A measurable and quick ROI is possible just by retrofitting your static pallet rack with dynamic SpeedCell.

The SpeedCell Advantage

The space, time, and cost savings proven by implementing SpeedCell are clear, but what are some of the other advantages? Here’s how static shelving compares to SpeedCell high-density storage.

Pallet Rack with Wire Deck and Static Industrial Shelving

- Fixed shelf heights decrease space utilization

- Larger footprint increases walking time for workers

- More walking creates lower pick rates

- Static storage creates “dead zones” on shelves

- No built-in organization system

- Boxes may need to be cut open if not decanted

SpeedCell Dynamic Shelving

- Integrates into existing pallet rack structures

- Increases SKU density and accessibility by utilizing the maximum amount of space within racks

- Allows storage of more SKUs in less space

- Boosts storage density by 40-60%

- Labeled cells increase inventory, efficiency and accuracy of every pick

- Compatible with pick-to-light, RFiD and scanners

- Lowers labor costs up to 40% by reducing walking time for workers

- Provides easy access to every SKU, improving workplace ergonomics for less risk of injury

Maximize Space with UNEX SpeedCell

SpeedCell high-density storage transforms warehouse efficiency by maximizing SKU density, eliminating wasted space, and significantly reducing picking time. Compared to pallet rack with wire deck and static industrial shelving, SpeedCell allows facilities to store more in less space, cut down on worker travel time, and lower operational costs.

Beyond cost savings, SpeedCell improves ergonomics, reduces mis-picks, and streamlines fulfillment operations, leading to a faster return on investment. If you're ready to increase efficiency, contact us today to learn how SpeedCell can fit into your existing storage system.