4 Benefits of Implementing High-Density Storage Solutions

Warehouse operators are under pressure to do more with less; less space, fewer workers, and tighter margins. At the same time, customer expectations for fast, accurate fulfillment have never been higher. With SKU counts climbing and real estate costs soaring, warehouse storage strategies that once worked are now holding facilities back.

That’s where high-density storage comes in. By transforming unused or inefficiently used areas into organized, accessible inventory zones, high-density solutions give operations the breathing room they need to meet demand without expanding their footprint. The result is a smarter, more resilient warehouse that can scale to meet both current challenges and future growth.

Yet not all high-density solutions are created equal. What separates effective systems from gimmicks is how well they integrate with picking workflows, SKU variety, durability, and ROI expectations. In this blog, we’ll walk through four foundational benefits of high-density storage.

The Case for High-Density Storage in Today’s Warehouses

High-density storage isn't just about stacking more product into less space. It’s a strategy for achieving multiple operational wins at once, from labor efficiency and order accuracy to employee safety and customer satisfaction.

Before diving into how operations benefit from implementing high-density storage solutions, let’s underscore the market forces driving adoption of dynamic storage systems:

- Evolving fulfillment demands. Retailers and 3PLs must handle unpredictable demand swings, micro-fulfillment, and a growing long-tail of SKUs. Static shelving often becomes a bottleneck.

- Labor scarcity and cost pressures. Fewer workers, higher wages, and rising turnover mean that incremental productivity gains are no longer optional.

- Rising real estate costs and footprint constraints. The cost of building or leasing additional warehouse space continues to outpace returns, making warehouse space optimization more cost-effective than expansion.

- Technology convergence. The warehouse of 2025 and beyond will be a blend of dense storage, automation, robotics, and real-time analytics. High-density storage is foundational for many “goods-to-person” and AS/RS hybrid systems.

Given this backdrop, investing in warehouse space optimization isn’t a “nice add-on," it’s becoming a baseline expectation for competitive fulfillment operations. Below are four benefits that every operation should expect from a mature, dynamic high-density storage system.

The 4 Key Benefits of High-Density Storage Solutions

It’s important to recognize that high-density storage is more than just a space saver. It’s a tool that aligns with broader business goals, whether that’s increasing fulfillment speed, improving worker safety, or boosting overall profitability. A well-designed high-density storage system impacts nearly every corner of the warehouse, from how products are received and stored to how quickly and accurately they leave.

Companies that successfully implement high-density solutions often find that it transforms not only their storage footprint but also their operational mindset. Instead of constantly fighting for space, managers can focus on efficiency, growth, and customer satisfaction. And for workers on the floor, a cleaner, more organized environment means less frustration, fewer errors, and better ergonomics. These ripple effects are why density has become a competitive differentiator, not just a facility upgrade.

1. Save Space Without Expanding Your Footprint

The clearest benefit of high-density storage systems is in squeezing more inventory into the same building. Rather than rethinking or expanding facilities, which carry massive costs, permitting challenges, and operational disruption, these systems convert “dead” or underutilized zones into usable pick space.

Instead of making the financial investment to expand the existing warehouse footprint, high-density storage solutions save space and increase throughput. To maximize storage capacity, high-density storage systems create vertical columns, resulting in better cube utilization and increased pick facings.

For example, UNEX SpeedCell can compress 200 feet of shelving or rack into just 40 feet of highly organized pick space. Many users report a 40–60% increase in storage density without changing the building footprint. This kind of space optimization allows warehouses to avoid expansion costs, reduce lighting/energy overhead, and preserve agility in a volatile fulfillment environment.

2. Shorten the Pick Path and Improve Throughput

Every extra foot a picker walks is an opportunity cost. Dynamic high-density storage systems radically reduce pick line length by consolidating pick facings into compact zones, which directly translates to greater throughput per hour.

Because high-density storage systems pack SKUs closer together, workers spend less time moving between aisles and more time picking. The net effect: more picks per labor hour, smoother workflows, and improved overall volume handling.

3. Reduce Picker Search Time and Increase Accuracy

Storing SKUs in widely dispersed zones leads to elevated search time, mis-picks, and downtime. In contrast, high-density storage solutions often incorporate labeled cells or structured layouts so that each SKU has a clear, visible home.

With a system like SpeedCell, cells slide side-to-side, label holders are built in, and SKU visibility is improved, meaning pickers find items faster and make fewer mistakes. For example, if a company with a 25-person staff increases pick rates by 20%, they can achieve an extra 2,400 picks per day or over 600,000 picks per year. Since that increased number of picks doesn’t involve hiring and training additional staff members, companies benefit from more orders fulfilled with the same staff size.

4. Prevent Product Damage, Loss & Safety Incidents

As warehouse operations become denser, the risk of inventory damage or workplace accidents rises, unless the system is designed correctly. High-density storage systems mitigate these risks with partially enclosed cells, stable containment, and ergonomic layouts, reducing overreaching, bending, or risky moves.

Specifically, the design of SpeedCell protects slow-moving inventory from dust, contamination, and accidental drops. The enclosed nature of the cells helps prevent items from falling and injuring workers or being damaged. This protective layer adds quality-of-service assurance (less shrink, better product condition, safer operations) on top of productivity gains.

Discover a high-density storage solution and get the Ultimate Order Fulfillment Checklist! Download the Meet SpeedCell Guide.

From Benefits to Real-World Results

The theoretical benefits above are powerful, but real-world ROI matters most. Many high-density systems that promise “density” fall short on ergonomics, integration, or durability.

That’s where UNEX SpeedCell stands apart. SpeedCell isn’t just another shelving add-on, it’s a dynamic, high-performance solution architected for fulfillment environments.

What Is SpeedCell & How It Works

SpeedCell is a dynamic high-density storage system that operates within existing pallet racking and pick modules. Rather than static shelving, it uses textile-based, interwoven mesh columns that slide laterally to expose internal SKU storage zones.

SpeedCell is a dynamic high-density storage system that operates within existing pallet racking and pick modules. Rather than static shelving, it uses textile-based, interwoven mesh columns that slide laterally to expose internal SKU storage zones.

Dead space behind racks, under mezzanines, or between structural bays becomes a dense pick zone. The high-density storage solution is modular and available in six column sizes (XS to XXL), making it suitable for a wide variety of SKU densities.

Key Benefits of SpeedCell:

- Space compression: Up to 200’ of shelving reduced to 40’ of efficient pick space

- Density gains: 40–60% more storage capacity compared to static shelving

- Labor efficiency: Up to 40% reduction in labor costs thanks to shorter travel and search times

- Durability & ergonomics: Mold- and flame-resistant textiles, ergonomic access to all SKUs, safer working conditions

- Proven results: Goodwill Industries of Central and Southern Indiana increased storage capacity by 30%, eliminated over 3 miles of wasted employee walking each day, and boosted output, all without expanding their footprint.

Applications Across Industries:

- eCommerce fulfillment centers managing thousands of SKUs

- Retail backrooms needing flexible, compact storage

- 3PLs and logistics providers handling diverse product profiles

- Warehouses balancing slow-, medium-, and fast-moving inventory in one system

Turning Space into Savings with High-Density Storage

Space optimization isn’t just about fitting more inventory under one roof, it’s about creating a smarter warehouse that drives profitability, safety, and customer satisfaction.

High-density storage systems make this possible, and UNEX SpeedCell goes a step further by offering a proven, flexible, and ROI-driven solution.

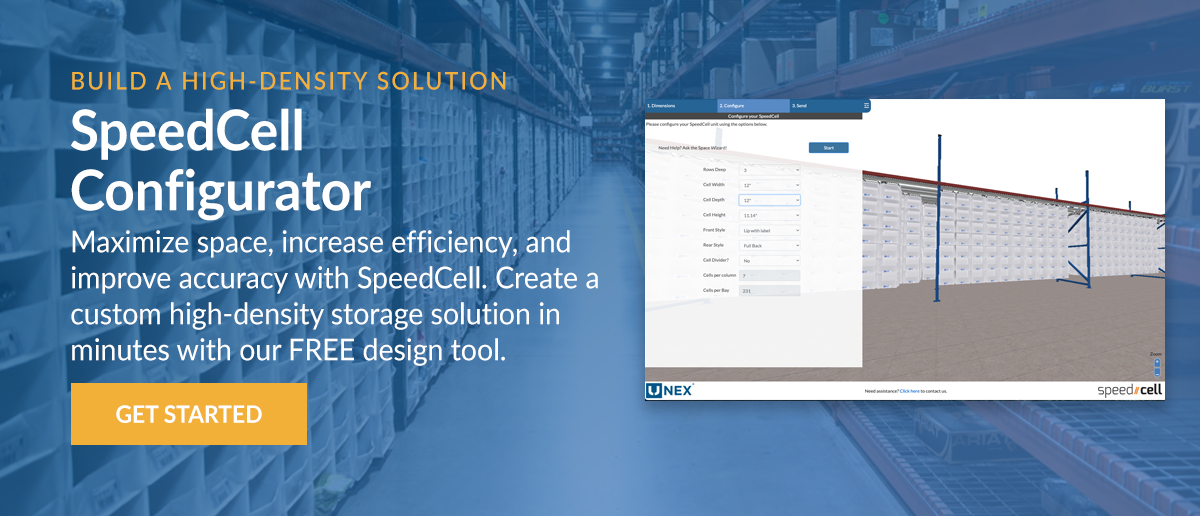

Want to see how much space, time, and cost you could save with SpeedCell? Try the SpeedCell Configurator today or contact our experts to start designing a solution tailored to your operation.