Whether your warehouse has hundreds or thousands of unique SKUs, there are endless ways to organize and structure your inventory. Pick modules are a vital component of inventory storage for many operations. They are single, or multi-layer engineered structures that use various warehouse storage systems to store inventory for order fulfillment.

An effective pick module optimizes warehouse layouts and streamlines order fulfillment, reducing the time order pickers spend searching for and picking SKUs. When well-optimized, pick modules can increase order accuracy and streamline manual picking tasks. However, poor optimization causes the following problems:

- Wasted space: Warehouse space is valuable, and underutilized space negatively impacts your bottom line.

- Inefficient pick paths: These can increase order fulfillment time, cause order errors, or create hazards that result in workforce injuries.

- Inaccurate inventory: Disorganization at pick locations can cause backlogs and other inventory issues.

While these order picking problems are common in warehouses and order fulfillment centers, they’re also preventable. From analyzing SKUs to investing in more space-efficient storage systems, there are numerous strategies and best practices that you can follow to optimize your pick module.

What to Consider When Optimizing Your Warehouse Pick Module

Before you can optimize your pick modules for maximum efficiency, you need to analyze your current operations. What type of order picking methods are you currently using in your facility? How is your warehouse laid out? Are your workstations set up to reduce fatigue and workplace injuries?

Once you understand the ins and outs of your current operations, consider implementing these pick module best practices and strategies.

1. Analyze SKUs and Storage Needs

To better understand what storage systems are ideal for your pick module, you need to analyze and organize your SKUs. We recommend categorizing your SKUs as fast, medium, or slow movers based on throughput. Product type and similarity, as well as seasonality should also be taken into consideration. Here’s a brief overview on throughput to help you better organize SKUs in your pick module:

- Slow movers: These SKUs are ordered infrequently. While slow movers don’t need a high-profile position in your warehouse, they still need to be stored in an easily accessible location.

- Medium movers: Medium-throughput SKUs typically represent the bulk of an operation’s picks and are each or case picks.

- Fast movers: Your fast-moving SKUs represent most of your facility’s revenue stream. Usually, they consist of a pallet or more of throughput per shift.

Warehouse throughput refers to the number of units processed per time interval. By categorizing SKUs as fast-, medium-, and slow-throughput, you can:

- Optimize the cubic space in your warehouse

- Minimize time spent searching for misplaced SKUs

- Ensuring pick paths are as efficient as possible

- Increase speed while driving down costs

Shaving just 10 seconds off the time it takes an order picker to locate, pick, and deliver medium-throughput SKUs will increase capacity (by 100 picks per day) and reduce variable costs (a 20% reduction). This is an example of why it’s essential to implement pick module storage solutions for throughput.

2. Implement Right-Sized Storage Solutions

After categorizing your inventory, you can then choose the best types of storage systems for your pick module, ensuring storage is as efficient as possible for all SKU types:

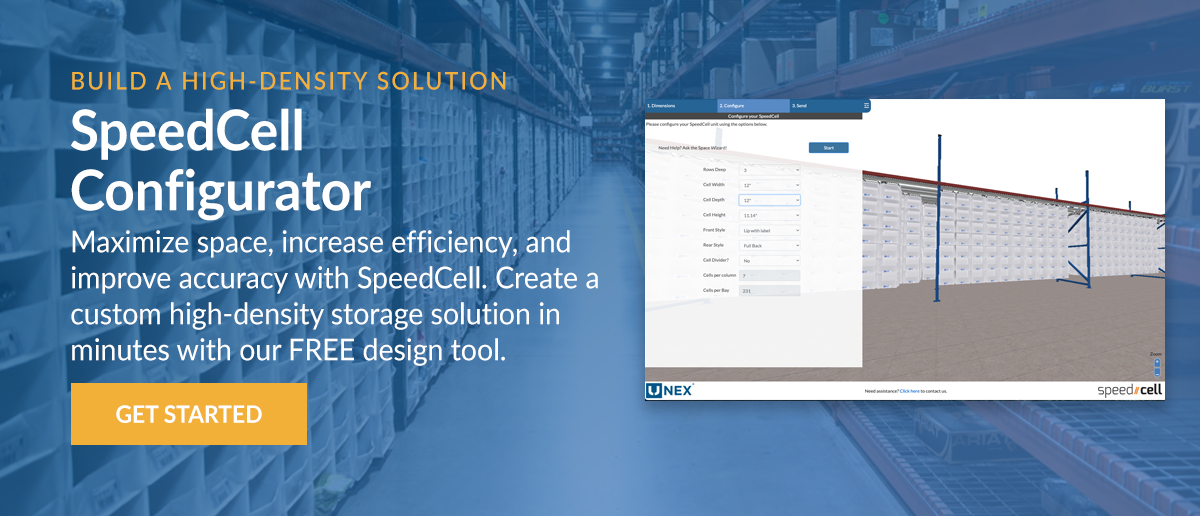

Slow Movers: SpeedCell

Slow Movers: SpeedCell

We recommend static shelving, tilted-pick shelving, or a high-density dynamic storage system, such as SpeedCell, for slow-moving SKUs. A storage solution like SpeedCell maximizes space utilization within standard pallet racking, creating a highly efficient and accurate pick. SpeedCell has been shown to increase storage density by up to 60% while reducing labor costs.

Medium Movers: SpanTrack

Medium Movers: SpanTrack

For medium movers, carton flow storage systems, like SpanTrack, are an ideal solution to optimize picking. SpanTrack is fully customizable. For each picking, it can be configured with adjustable pick trays, allowing order pickers to pick products from open cases without interference from the shelving above. SpanTrack can also optimize first in, first out (FIFO) storage lanes, which are essential for full case picking. Overall, SpanTrack maintains organized pick faces and improves throughput by up to 150%.

Fast Movers: Pallet Track

Fast Movers: Pallet Track

Fast-moving SKUs are best left on a pallet or loaded into a pallet flow system, such as Pallet Track, for speed. A solution like Pallet Track lets you store a pallet on a pitched conveying surface. The pitch enables your order pickers to move pallets forward quickly and easily as other pallets are emptied. Pallet Track provides FIFO replenishment to your pallet positions and is fully customizable to meet the unique needs of your operation. UNEX Pallet Track eliminates double handling and reduces restocking requirements by 50%.

3. Consider Conveyors

To decrease the amount of time order pickers spend walking, utilize conveyor systems, like gravity conveyors to move orders throughout your warehouse.

To decrease the amount of time order pickers spend walking, utilize conveyor systems, like gravity conveyors to move orders throughout your warehouse.

Gravity conveyors move packages without using electricity. Instead, they use wheels or rollers to move items along. They can move orders from your pick module to your warehouse’s shipping area, eliminating the need for employees to push or pull boxes manually as they move through the pick module and into other areas of your operation.

Takeaway conveyors are commonly incorporated into pick modules and installed between aisles. Order pickers can select the SKUs for their orders. Then, the takeaway conveyor moves the order to the next picking zone until it’s ready for packing. Takeaway conveyors can be motorized, but the most cost-effective, space-efficient, and high-performing, durable solution is UNEX Gravity Conveyor.

When used strategically throughout your operation, gravity conveyors reduce wasted motion and streamline the fulfillment process in pick modules and numerous other areas of an operation.

4. Focus on Ergonomics and Picker Productivity

Order picking is essential in any warehouse, impacting your operation’s output and bottom line. But if a warehouse isn’t correctly configured for order pickers — inaccessible shelves are just one example — it can cause employee fatigue, impacting workplace safety and your business’s efficiency.

To enhance picker productivity, accuracy, and speed, we recommend implementing the following strategies, all of which apply to optimizing warehouse pick modules:

- Improve access to SKUs: Are your SKUs easy for pickers to access? Are workers awkwardly bending down or reaching up to pick SKUs? You can eliminate unnecessary strain by implementing dynamic storage solutions that eliminate dead zones in shelving. Focus on storing products in easy-to-reach locations. In each picking operations, use angled shelving or carton flow with knuckled end treatments to angle SKUs toward pickers for increased visibility and accessibility.

- Adjust warehouse layout: If your goal is to improve picker productivity, take a look at your pick module layout. Is there enough space between aisles? Are workspaces large enough to incorporate additional staff during busy times? Is there a lot of distance between picking locations? In addition to implementing space-efficient, right-sized storage mediums, you may also need to make changes to your facility’s layout. This is something that should be monitored and tweaked over time, and the flexibility offered by dynamic storage solutions simplifies warehouse re-organization.

- Invest in additional material handling equipment: How are your orders moving from your pick modules once they’re ready for shipping? While warehouse employees can move them manually, equipment like gravity conveyors can ease the strain on workers so they are 100% focused on picking. Other equipment like picking carts can be very beneficial to increasing pick speeds in your pick module. UNEX SpeedCartt is a mobile order picking cart that is great for organizing restocking, order fulfillment, seasonal demands, and more. SpeedCartt is reliable even in the most demanding warehouse environments and can significantly increase efficiency in pick modules.

Optimize Your Pick Module with UNEX Dynamic Storage Solutions

Storing SKUs according to throughput, implementing space-saving dynamic storage systems, and focusing on workplace ergonomics can help transform your current pick module setup into a more efficient order picking operation.

Dynamic storage solutions from UNEX, like SpeedCell, SpanTrack, and Pallet Track enable warehouses to fully utilize their available space while improving pick rates and accuracy and increasing SKU density. UNEX solutions are ideal for optimizing pick modules to meet and surpass your efficiency goals.

If you would like to learn more about how our dynamic storage solutions can increase efficiency in your pick modules, we’ve got you covered. Contact our team of experts get on your way to better pick module optimization today!

Slow Movers: SpeedCell

Slow Movers: SpeedCell  Medium Movers: SpanTrack

Medium Movers: SpanTrack Fast Movers: Pallet Track

Fast Movers: Pallet Track To decrease the amount of time order pickers spend walking, utilize conveyor systems, like gravity conveyors to move orders throughout your warehouse.

To decrease the amount of time order pickers spend walking, utilize conveyor systems, like gravity conveyors to move orders throughout your warehouse.