Solution Spotlight: Shelf Track Carton Flow Shelving

Carton flow storage is an essential component of efficient warehouse operations. By utilizing gravity to smoothly move inventory from loading to pick locations, carton flow optimizes picking, maximizes storage density, and promotes first-in-first-out (FIFO) stock rotation. However, using plastic wheel rail systems or basic static racks often leave much to be desired.

On a good day, you or your workers may only have to use a shepherd's hook a few times during a shift to pull down the cartons that simply won't flow down the rails. Much of the time that could be spent picking orders is instead spent on dealing with those inadequacies.

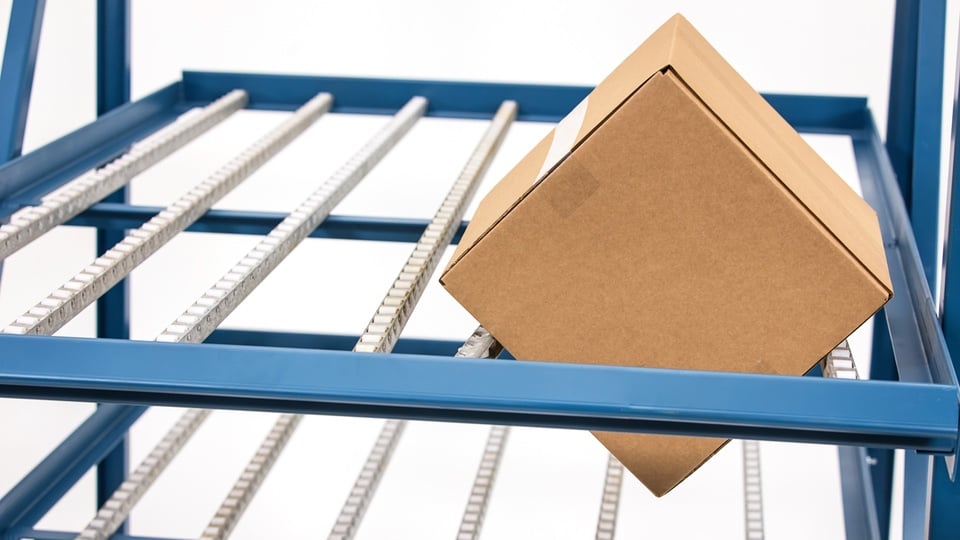

Shelf Track is a carton flow solution engineered to solve the pain points of those systems.

The Challenges of Unreliable Plastic Wheel Rails

Many warehouses still rely on plastic wheel rail carton flow systems or static racks where inventory sits on shelves waiting for manual replenishment. But these storage methods come with a number of downsides:

- Wheels constantly pop out and crack, stopping the flow of cartons

- Rails slide out of place and bunch up, causing bottlenecks

- Cartons drop through or get wedged in gaps between rails

- Weight of cartons causes rails to bow and bend over time

- Workers spend more time unjamming cartons than actually picking

Plastic wheel rails simply don't provide reliable, durable carton flow. Cartons get stuck, inventory piles up, and workers waste time dislodging stuck product. This results in inefficient picking, reduced storage density, and poor organization. Not to mention increased costs from broken components.

Related Reading: Carton Flow Shelving: Problems and Solutions

Introducing Shelf Track: Unrivaled Carton Flow

The engineers at UNEX recognized the need for a plastic wheel rail replacement and developed a more effective and durable carton flow shelving solution you can retrofit to your existing racks. Shelf Track is designed specifically to drop into existing structures and is engineered to work with any shelf or accessory you may be using in your facility. Instead of single lanes of plastic wheels, Shelf Track is available in both carton flow rollers and wheel beds to ensure your specific storage requirements can be met.

Shelf Track provides the smooth, seamless carton flow warehouses need. This system from UNEX retrofits into your existing racks with:

- Durable steel roller lanes and wheel beds

- Modular components for total flexibility

- Reliable construction backed by a 7-year warranty

By leveraging gravity, Shelf Track eliminates the need for constant manual replenishment. Inventory flows automatically from back to front as workers pick, keeping your fastest movers always accessible.

Shelf Track's heavy-duty steel carton flow solution will save you time, money, and headaches. And transform the way your warehouse operates.

The Benefits of Shelf Track Carton Flow

By replacing plastic rails with heavy-duty steel components, Shelf Track delivers transformative benefits:

- No More Hang-Ups — The durable steel construction prevents cracked wheels and bent rails that cause carton jams. Inventory glides smoothly from back to front.

- Low Maintenance — No more constantly realigning and replacing broken plastic wheels and rails. Shelf Track's sturdy steel system just works.

- Unrivaled Flow — The expanded surface area provides complete support across all carton contact points for seamless flow.

- Universal Compatibility — Shelf Track works with any existing shelf or rack system thanks to its drop-in design. Retrofitting couldn't be easier.

- Optimized Accessibility — The front-feeding flow creates an easily accessible pick point for workers.

Shelf Track transforms carton flow storage. Workers can pick faster and smarter, reducing labor costs and increasing throughput.

.png?width=800&height=533&name=UNEX%20-%20Shelf%20Track%20-%20Carton%20Flow%20Rollers%20(1).png)

Carton Flow Shelving Solution

Shelf Track offers two carton flow solutions — roller lanes and wheel beds — engineered to drop into existing racks and shelves. While both options retrofit into your existing racks and provide smooth, durable steel construction, there are some key differences between the lane and bed systems:

Carton Flow Shelving Roller Lanes

Shelf Track roller lanes provide 300% more contact surface area than plastic wheel rails. This reduces imprinting on your cartons, and guarantees that your product won't get hung up on a busted rail or slip between rails. UNEX Shelf Track carton flow shelving provides superior flow to plastic wheel rails, allowing you to pick orders without the need for a shepherd's hook.

- Can handle cartons up to 3" wider than the lane on each side

- Choose the roller spacing based on carton length for optimal flow

- Stops at the end keep cartons contained on the lanes

Carton Flow Shelving Wheel Beds

Shelf Track wheel beds offer superior flow from one end of the rack to the other allowing 90% left to right usage of the bay. Wheel carton flow beds allow you to reslot as you see fit, eliminating the need to rearrange your plastic wheel rails to make sure different-sized cartons don't drop between them. UNEX Shelf Track wheel beds utilize our innovative Hex Hub wheel design, allowing for uninhibited flow. Our Shelf Track carton flow shelving solutions are engineered with steel channels and axles, meaning the system can hold up under the pressure and won't bow due to the weight of cartons.

- Maximum flexibility left-to-right for reslotting

- Shark fin infeed guides ease replenishment

- Reslot carton lanes easily without rearranging components

- Hex hub wheels drastically reduce friction for smooth flow

UNEX Shelf Track carton flow shelving wheel beds and roller lanes are backed by our industry-leading seven-year warranty. Shelf Track is guaranteed to decrease pick times and increase your operation's efficiency when compared to unreliable plastic wheel rails.

Contact our Space Optimization experts to learn more about the benefits of Shelf Track or request a product sample kit to see our carton flow shelving solution in person!