Types of Industrial Shelving: From Static to Dynamic Storage Solutions

In today’s warehouses and distribution centers, storage decisions are no longer just about finding a place to put products. With SKU counts climbing, labor costs rising, and customer expectations accelerating, the shelving you choose plays a direct role in your ability to stay competitive. Industrial shelving is no longer just a matter of durability, it’s a strategic driver of space efficiency, throughput, and even worker safety.

There are several different types of industrial shelving available on the market today. With so many options, and some hidden nuances to each, it can be hard to determine what you really need. Below, we’ll walk through the four most common types of industrial shelving, their strengths and limitations, and how organizations are evolving toward high density storage solutions that unlock greater efficiency.

Common Types of Industrial Shelving

If you're searching for industrial shelving, what do you need to know? Below we are breaking down the basics of four most common types of industrial shelving and the typical use for each.

1. Boltless Shelving

Boltless shelving, also called rivet shelving or bulk shelving, is one of the most widely used forms of industrial storage because of its affordability and flexibility. These shelving units typically feature a solid steel frame with particle board or wire decks, and they’re extremely easy to assemble without tools. The boltless design makes them a cost-effective, accessible option for small operations or environments where storage needs change frequently.

Like steel shelving, boltless shelving can handle heavier loads and is suitable for high density storage applications. It can be configured as open or closed units depending on fire safety requirements. However, it is not as customizable as steel shelving when it comes to accessories like dividers or drawers. For facilities looking for a simple, economical solution that balances strength and ease of installation, rivet shelving is often the go-to choice, though many find themselves outgrowing it quickly as SKU counts rise and throughput demands intensify.

2. Steel Shelving

Steel shelving is the quite possibly the most popular type of industrial storage. Built for strength and longevity, steel shelves can handle heavy loads and withstand years of use, which makes them one of the most common and versatile options across many industries. They are usually easy to assemble and can be accessorized with dividers, drawers, or other add-ons to meet specific needs.

Units can be open or closed, though closed back units may not always meet fire code requirements, so compliance should be considered when selecting a configuration. Perhaps the most important factor to consider is the weight of the items being stored and how frequently they need to be moved. Steel shelving excels at storing heavier loads and, because of its versatility, shelves can be installed very close together, creating a strong setup for high density applications and operations with low-throughput SKUs. At the same time, the very qualities that make steel shelving durable and dependable can also make it inflexible. It is static, rigid, and less adaptable when SKU profiles change, and for some businesses it can consume valuable space without offering the scalability of more dynamic storage solutions.

3. Wire Shelving

Wire shelving, sometimes called wire rack, is known for its open design, which improves airflow and visibility. It is often the shelving of choice in industries like food, beverage, and healthcare where sanitation and compliance are non-negotiable, and you’ll also find it in warehouses, retail backrooms, and even homes because of how easy it is to assemble.

The open construction of wire shelving is great for meeting fire code concerns, and its lightweight frame means wire shelving can be mounted on casters to create mobile units. It is also mold- and rust-resistant, and it won’t collect dust like steel or rivet shelving, which makes it particularly well suited for clean environments. The tradeoff, however, is a lower weight capacity and limited ability to support dense storage or high-volume picking. Wire shelving works well in lighter-duty, specialized applications but is not equipped to address the pressures of rapid SKU growth or the demands of large-scale fulfillment.

4. Dynamic Shelving

Dynamic shelving represents the evolution of industrial storage. Unlike static shelving, dynamic storage systems are movable within the rack itself, often consisting of rugged yet lightweight columns that slide side to side on a track. These columns are typically made of fire-, rust-, and mold-resistant materials, making them ideal for clean applications and environments with strict fire safety requirements.

Because they are compatible with standard pallet rack, dynamic shelving can be installed directly into existing structures, offering a cost-effective way to dramatically increase storage density. This maneuverability allows for multiple rows of storage within one rack, condensing standard shelving to create far more SKU locations. Dynamic shelving maximizes SKU density, improves pick efficiency, and supports lean warehouse practices. It is particularly effective for high-density storage applications with slower-moving products, but it also plays a critical role in eCommerce and omnichannel fulfillment, where efficiency and space optimization are essential. By transforming static space into organized, high-density storage, dynamic shelving turns industrial storage into a true competitive advantage.

Learn how to save space in your facility. Download The Guide To Optimizing Warehouse Space Utilization!

Challenges Static Shelving Can’t Solve

Even the best static shelving has limits, and those limits become more pronounced as warehouses and distribution centers grow busier and more complex. Static shelving often fails to support the level of efficiency, adaptability, and safety required in modern operations. Key challenges include:

- Space Utilization: Static shelves quickly max out when SKU counts rise, leaving vertical and horizontal space underutilized.

- Labor Costs: Workers must travel farther to pick items, which increases labor costs and slows throughput.

- Ergonomics: Reaching, bending, and lifting from static shelving creates fatigue, safety risks, and lost productivity.

- Scalability: Static shelving cannot adapt to seasonal peaks, SKU proliferation, or rapid business growth.

- Inventory Control: Limited ability to support FIFO and lean practices leads to wasted space and inefficiencies.

These challenges are why many organizations are adopting dynamic storage solutions. High density storage systems provide the flexibility and efficiency static shelving simply cannot deliver.

Dynamic shelving addresses these challenges head-on by rethinking how industrial storage works. Instead of expanding your warehouse footprint, dynamic storage solutions make better use of the space you already have. High density storage allows more SKUs to be stored in the same footprint, while organized product placement makes picking faster and reduces travel time. This efficiency translates into lower labor costs, and because dynamic shelving systems can expand and adapt, they support scalability far better than static options. For businesses competing in today’s fast-paced supply chain environment, dynamic shelving is becoming less of a luxury and more of a necessity.

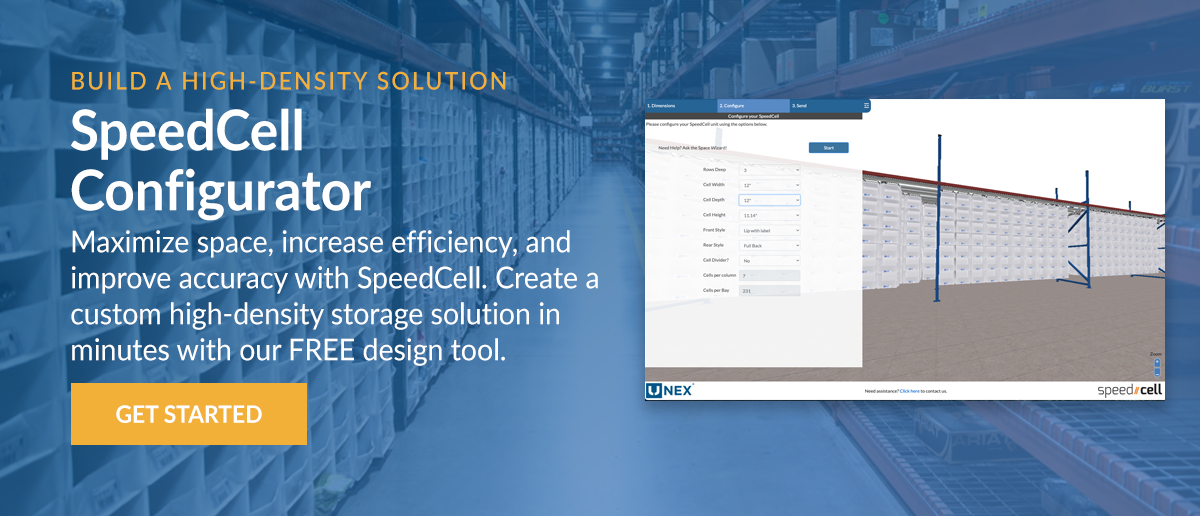

UNEX Solution: SpeedCell

When it comes to dynamic shelving, UNEX SpeedCell sets the standard for high density storage systems. SpeedCell is a column-based industrial storage solution made of high-strength textiles suspended within standard pallet racking. It transforms empty vertical space into organized, accessible pick faces, enabling facilities to store more and pick faster within their existing footprint.

The SpeedCell Advantage:

The SpeedCell Advantage:

- Maximize Space: Compress up to 200 feet of static shelving into just 40 feet of dynamic storage.

- Increase SKU Density: Dramatically expand the number of pick facings available within the same footprint.

- Boost Efficiency: Reduce picker travel time by up to 40% and accelerate order fulfillment.

- Cut Labor Costs: Improved efficiency lowers the cost per pick and helps alleviate labor shortages.

- Improve Ergonomics: The ergonomic design of SpeedCell reduces the need for reaching, bending, and stretching, protecting workers from fatigue and injury.

- Durable & Clean: Flame-, rust-, and mold-resistant textiles withstand demanding environments and support applications where sanitation and fire safety matter.

- Scalable: Adapts to SKU growth, seasonal fluctuations, and the evolving demands of eCommerce and omnichannel fulfillment.

By delivering both high-density storage and greater flexibility, SpeedCell shifts industrial storage from a static necessity to a strategic advantage.

Create Your Own Industrial Shelving Solution

Industrial shelving decisions shape more than just how products are stored, they influence efficiency, labor costs, worker safety, and a facility’s ability to scale. Boltless, steel, and wire shelving each have their place, but they often fall short in addressing today’s challenges of SKU growth, labor constraints, and customer demand.

Dynamic storage solutions, like SpeedCell, represent the future of industrial storage. By providing high density storage and improving pick efficiency, SpeedCell helps organizations do more with less. More SKUs in less space, more orders in less time, and more productivity without additional square footage.

For businesses ready to move beyond static shelving, SpeedCell offers a clear path forward. Contact us today to learn more about our engineered space optimization solutions and how we can help you maximize your storage capacity and improve efficiency in your warehouse or fulfillment center.