SpanTrack Lane Carton Flow Rollers

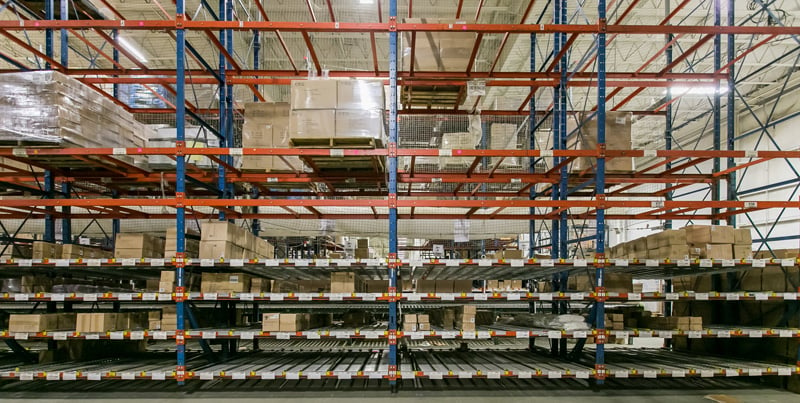

Efficient, durable, and dependable, SpanTrack Lane carton flow rollers drop into existing structures to create the ultimate carton flow rack system for manufacturing facilities and order picking operations.

Carton flow is a fantastic SKU storage solution that increases efficiency across a diverse range of operations, but what are some of the key advantages of implementing this type of dynamic storage system? In this article, we will take a deep dive into the advantages of implementing SpanTrack carton flow. We’ll answer the basics like, “What is carton flow?” and “What is SpanTrack?” Then, we will provide a detailed breakdown of the space and cost-saving benefits of SpanTrack carton flow. Let's get started!

Carton flow, also known as flow racking, roller racking, and gravity flow, is a dynamic storage solution that can dramatically improve space utilization and order picking efficiency within a warehouse. Carton flow is made of roller or wheel-based conveyors. These conveyors are designed to create lanes of storage within pallet racking. These storage lanes use gravity to flow products through the rack to allow for streamlined replenishment and order picking.

Most carton flow comes in a variety of options like light-duty, standard-duty, and heavy-duty; steel and aluminum rollers; plastic wheels or steel skatewheels. Carton flow is ideal for facilities with case picking and/or each picking operations and is a key component to order picking efficiency when storing items according to throughput. Carton flow is a great solution for many SKU varieties but is best suited for the medium to fast-moving products that make up the majority of an operations inventory.

SpanTrack is The Original Carton Flow Track! Whether you have bulky boxes to store, SKUs to move, or orders to fulfill, SpanTrack provides the most reliable, durable, and efficient carton flow systems in the industry. Carton flow rack systems dramatically improve productivity and accuracy on the pick line, maximize SKU storage, and minimize strain on pickers, and SpanTrack is no exception.

While there are several carton flow solutions on the market, there are a few key differentiators that make SpanTrack the leading carton flow solution and one that businesses have trusted for decades. Here are the top 3 reasons why SpanTrack is a superior carton flow solution:

1: SpanTrack carton flow solutions provide the most surface contact, so weight is distributed evenly to optimize product flow and eliminate hang-ups on the track.

2: SpanTrack increases throughput by up to 150% compared to picking from pallets.

3: SpanTrack’s patented design easily drops into existing structures with very little effort and is backed by an industry-leading 7-year warranty.

Efficient, durable, and dependable, SpanTrack Lane carton flow rollers drop into existing structures to create the ultimate carton flow rack system for manufacturing facilities and order picking operations.

UNEX engineered-to-order carton flow rollers provide the most surface contact to optimize carton flow, eliminate hang-ups on the track, and increase throughput.

SpanTrack Wheel beds are flexible carton flow beds that drop into existing structures to create the ultimate flow rack system for order picking operations, manufacturing facilities, and more.

Durable and dependable SpanTrack carton flow beds maximize space and throughput for inventories of varying shapes and sizes. Our engineered-to-order universal carton flow beds create superior flexibility and increase space utilization throughout your operation.

Efficient, durable, and dependable, SpanTrack Lane carton flow rollers drop into existing structures to create the ultimate carton flow rack system for manufacturing facilities and order picking operations.

SpanTrack wheel beds are flexible carton flow beds that drop into existing structures to create the ultimate flow rack system for order picking operations, manufacturing facilities, and more.

Low Profile SpanTrack carton flow rollers drop into existing pallet rack, creating FIFO storage lanes that are ideal for full case picking. Designed to ensure FIFO product rotation, SpanTrack carton flow rollers present cases or cartons to workers so they can easily pick orders without having to reach and bend into racks. Storing products in carton flow racks condenses and organizes SKUs to reduce travel time and maximize space utilization.

SpanTrack carton flow rollers optimize each picking with adjustable pick trays that present open cases to order pickers. In each picking applications, workers pick products from split cases without interference from the shelf level above. SpanTrack can maximize space within your facility and increase throughput up to 150% compared to picking eaches from cases stored on pallets at ground level.

The key advantage of SpanTrack Wheel Bed is its ability to flood an entire level of pallet racking to maximize left-to-right flexibility with SKU slotting. Multiple-sized products can be positioned within the same shelf level, making both slotting and re-slotting simple.

When it comes to warehouse storage, SpanTrack carton flow helps order fulfillment operations, retailers, and logistics providers accelerate order picking processes. The space-savings are the most obvious benefit of implementing a carton flow system like SpanTrack. Maximizing space utilization within your racks sets you up for success in many areas of your order picking operation. Compared to static storage positions like picking from flat shelves or pallets stored on the floor, SpanTrack can dramatically increase efficiency in your warehouse.

In today’s competitive eCommerce, omnichannel fulfillment environment, order picking operations are less likely to be handling full pallets; instead, inventory is moved to the pick area in individual cartons, where pickers pull items to fulfill the more typical, smaller, multi-SKU order. In this type of application, using SpanTrack carton flow racks can increase operational efficiency by as much as 75%, often immediately.

Let’s further break down the key advantages of implementing SpanTrack carton flow for enhanced order picking.

1: Increased Space Utilization

2: SKU Organization, Accessibility, and Visibility

3: Reduced Labor Costs

4: FIFO Storage/Inventory Rotation

Carton Flow is an efficient and practical solution for increasing efficiency in your warehouse. By maximizing space utilization and creating a highly organized FIFO system, carton flow streamlines your order picking processes. Carton flow rack racking systems offer a range of benefits that can help improve your warehouse operations. From increasing efficiency to reducing labor costs, these systems can provide a significant return on investment. When choosing this kind of system, it is important to consider factors such as load capacity, product size, and storage density. It is also essential to properly maintain your system through regular inspections and cleaning to ensure it operates efficiently and safely.

Let the carton flow experts at UNEX help you design a SpanTrack carton flow solution that will work for the unique needs of your operation for decades. If you’re looking for a reliable and effective way to optimize your warehouse storage, contact UNEX to start exploring a SpanTrack carton flow system for your business.