How to Design Your Own High-Density Storage Solution

Today’s warehouse managers oversee more inventory than ever, and a growing volume and variety of SKUs mean warehouses face the ever-present challenge of limited space. But there are many ways to optimize the space in your warehouse — one way is by using a high-density storage system.

High-density storage solutions offer extreme SKU density, ensuring warehouse space is utilized to the max. Whether you’re planning for peak season or want to speed up your overall order fulfillment, this guide will cover the benefits of high-density storage and walk you through designing an efficient high-density storage solution that will meet the needs of your operation.

What Is High-Density Storage in a Warehouse?

A high-density storage system consolidates large volumes of products while maximizing limited warehouse space. These systems aim to occupy little space while storing as many SKUs as possible. There are different types of high-density storage, including:

- Static Shelving: This basic storage option assigns each SKU a fixed location on a stationary shelf. The most common types of static industrial shelving that could be used as a high-density storage solution are typically flat shelving units like rivet or steel shelving, or wire decking in pallet racking.

- Automated Storage & Retrieval Systems (AS/RS): These systems use automation to move SKUs from Point A to B. Cranes, shuttles, and vertical arousels are all common examples.

- Dynamic High-Density Storage: Dynamic high-density storage systems are designed for manual, person-to-goods order picking. Unlike their static and automated counterparts, dynamic storage systems are made for workers to hand-stock and hand-pick products from moveable shelving.

Discover a high-density storage solution and get the Ultimate Order Fulfillment Checklist! Download the Meet SpeedCell Guide.

Benefits of High-Density Storage Systems

There are multiple benefits of high-density storage systems. They help warehouses:

- Save Space: Rather than investing in a larger warehouse, high-density storage optimizes existing space.

- Shorten Pick Paths: By creating shorter pick paths, high-density storage can help boost productivity and increase the volume of orders picked per hour.

- Reduce Picker Search Time: When an order picker can’t find a SKU, the fulfillment process slows down. High-density storage condenses SKUs, increasing pick facings and lowering search time.

Before you can begin designing a high-density storage system for your warehouse, you’ll need to take into account several key considerations:

- What is your inventory like? The type of products you store determines what kind of storage you need. For example, do you need dry goods storage or cold storage? Do you need both? How big or small are the products in your warehouse?

- How big is your warehouse? How big is your warehouse? How much space do you have available? The size and shape of your building will determine the type of storage and layout that can be used.

- What is your budget? Your budget will ultimately determine what type of high-density storage solution will balance cost with your operational goals.

Design Principles for High-Density Storage

Are you ready to design your ideal warehouse layout leveraging high-density storage? When planning, consider these design principles:

- Space Utilization: High-density storage solutions maximize space utilization. They can compress rack or shelving (or completely replace it depending on the solution) into highly organized space. This helps warehouses improve pick speed and accuracy while increasing overall storage density. Storing more products in less space leads to greater efficiency.

- Accessibility: Your warehouse should be organized in a way that makes it quick and easy for employees to pick orders and conduct inventory counts. Slow-moving SKUs should be stored in a high-density storage solution so they take up less warehouse space but are always easily accessible.

- Flexibility: Is your warehouse designed for future needs and scalability? A good high-density storage solution will help your space become more flexible. Well-designed systems integrate seamlessly with existing equipment, making it easy to scale as you grow.

- Safety & Ergonomics: Safety and ergonomics should never be an afterthought. A well-planned, high-density storage solution is ergonomically designed to reduce the need for deep bending, stretching, or step stools.

Related Reading: Dynamic High-Density Storage and the SpeedCell Advantage

Planning Your High-Density Storage Solution

Ready to start planning a high-density storage solution to transform your operations? Follow these essential steps:

1. Conduct a Needs Analysis

The first step is conducting a needs analysis to help you understand your warehouse’s storage and retrieval needs. How much available space do you have? How much will be dedicated to storage, receiving, and shipping areas?

2. Categorize Your Inventory

Next, it’s time to organize your inventory according to throughput. Assess the following for each SKU:

- Fast-Movers: Not all SKUs need to be moved from a pallet position onto a shelf. For your very fast movers, double handling these SKUs is just not worth it. But instead of picking these pallets from static positions, storing high throughput items in a solution like UNEX Pallet Track will optimize pallet flow and help create an ideal FIFO inventory stock rotation.

- Medium-Movers: Medium-movers are generally best served by dynamic storage solutions like carton flow. UNEX SpanTrack is a great choice for your fast to medium-moving SKUs. SpanTrack can be added to any pallet rack and can store a wide variety of product sizes and weights. SpanTrack is designed to eliminate hang-ups and keep items flowing seamlessly to the point of pick. SpanTrack can be used for case picking or each picking.

- Slow-Movers: Slow-moving SKUs should be stored in static shelving or a high-density storage system like UNEX SpeedCell. SpeedCell can compress 200 feet of rack or shelving into a mere 40 feet. The greater SKU density means you can put all your slow-movers in one easy-to-reach place, reducing travel time and increasing pick accuracy.

Your slow-moving items are best stored in a high-density storage solution. These products are ordered infrequently and don’t need a high-profile position in your warehouse like your fast and medium-movers. Understanding throughput and how many slow-moving SKUs you have will help you configure the best high-density storage solution for your unique needs.

In addition to throughput, the size of your inventory matters. For example, you shouldn’t store tiny products in an extra-large pick face. On the other hand, you shouldn’t overstuff products in a too-small space either.

3. Layout Planning

Now that you’ve classified your inventory, you can begin planning the layout and configuration for your new or updated warehouse design. Where is automation possible, and where would it not make sense? How does the layout dictate the movement of products as they’re picked, packed, and loaded? Consider the proximity of your order picking areas to other critical areas like packing and shipping, for example, that will help ensure your overall order fulfillment process is smooth and efficient.

Whether you choose static shelving, AS/RS, a dynamic high-density storage system, or a combination of all three, you want to ensure you are properly assessing your needs and storing items according to throughput. Remember, this work is never done! Re-slotting your inventory over time is important to continually ensure you’re maintaining a healthy throughput.

UNEX SpeedCell: The Ultimate High-Density Storage Solution

SpeedCell is a durable and cost-effective dynamic storage solution — it can increase storage density in a given bay by up to 500%. Ideal for slower-moving products, SpeedCell helps warehouses across all industries and of all sizes maximize space utilization, increase SKU accessibility, and stay organized for faster order picking.

So, what makes SpeedCell so unique compared to other dynamic storage solutions? SpeedCell consists of columns made up of individual “cells.” Rugged and durable, these columns are made from high-strength industrial textures and are hung from a steel track suspension system using high-strength webbing — this alone sets SpeedCell apart from competitors.

One of the biggest benefits of using a dynamic high-density storage solution like SpeedCell is it eliminates dead zones. Every square inch of space within your racks is easily accessible, including the back rows. Workers can slide the rows of SpeedCell from left to right, reaching products without bending or reaching.

SpeedCell can hold up to 35 lbs in each cell. Each column is rated to hold up to 240 lbs. This extremely dense system helps warehouses drastically increase storage capacity, compressing 200 feet of rack or shelving into 40 feet of highly organized space.

Want to see SpeedCell in action? Discover how the world’s most extensive watersports and marine accessories dealer leverages SpeedCell — Overton’s saw efficiency improve by 20% to 30% and pick locations increase by 150%.

Learn how Overton's avoided costly warehouse renovations by implementing SpeedCell. Download the Case Study.

Design Your Own Dynamic High-Density Storage System

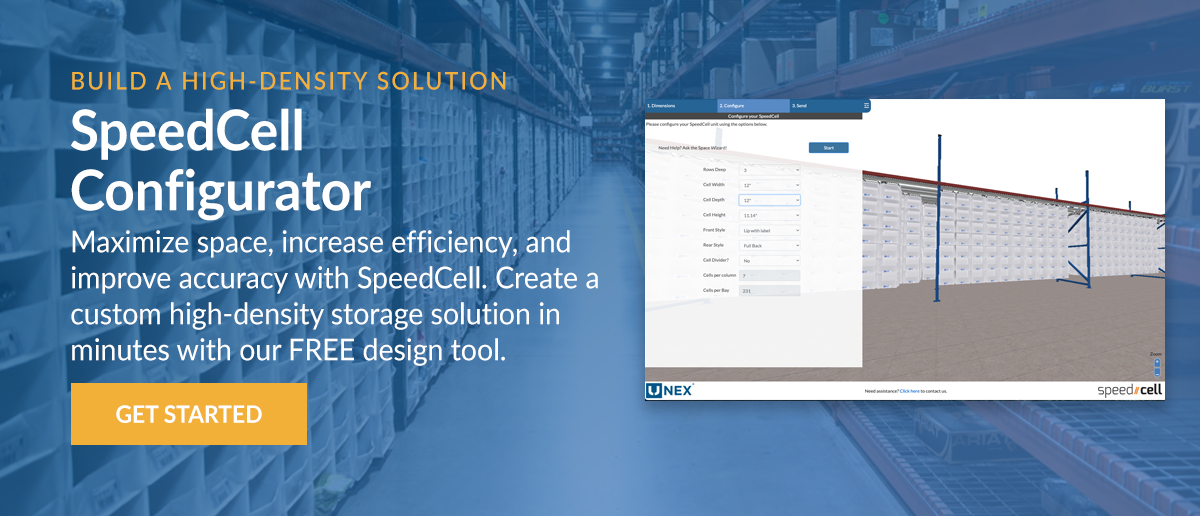

As you consider your options for high-density storage solutions, it can be overwhelming to ultimately make a decision. But Team UNEX is here to help! Our engineers created a free online product design tool that allows you to create your own dynamic high-density storage solution in a 3D sandbox environment. The UNEX SpeedCell Configurator will walk you through the steps to create a dynamic high-density storage solution to meet your needs.

The UNEX SpeedCell Configurator will walk you through these critical steps to designing the perfect high-density storage solution for your operation:

Choose Your High-Density Storage Dimensions

If you have existing pallet racking, you can define the dimensions, beam type, and size to determine which SpeedCell columns will work for your current space. If you need new racking, UNEX can supply it with our SpeedCell Ready Bay. Ready Bay is a complete, dynamic, high-density storage solution that includes SpeedCell columns, a pre-assembled steel suspension system, and a rack structure ready for use in minutes.

Configure Your SpeedCell High-Density Storage Columns

Whether you choose new or existing racking, SpeedCell comes in 6 standard sizes ranging from XS to XXL. You may be wondering how to choose which size is best for you. Selecting the right column size for your SpeedCell bay is simple; product size will be the primary factor in determining which size best suits your unique needs. The SpeedCell configurator will show you the exact column and cell dimensions, cells per column, cells per bay, and columns per bay based on the size you choose. This will help you determine how many pick locations each size will offer.

Get Your Free High-Density Storage Design

The last step is easy — provide your email address so we can send you a copy of your SpeedCell drawing and specifications straight to your inbox. Make as many designs as you’d like and, when you’re ready, our team of product specialists can help you make your final selections and get started on your project.

Unlock Your Warehouse's Storage Potential with SpeedCell

A well-planned warehouse optimizes your space while improving efficiency and keeping employees safe. Whether you’re considering a full warehouse redesign or reconfiguring certain areas of your facility, use this guide and the UNEX SpeedCell Configurator to spark ideas for your high-density storage solution. No matter your space or storage challenge, we’re here to help! Contact us today to speak to a product specialist.