SpeedCell for Each Picking Applications

Discover the power of dynamic high-density storage for each picking.

Each picking, also known as piece picking or split-case picking, is an order picking process in which a single item or SKU is picked from a master carton. These picks are typically bundled or packaged with other SKUs before being shipped.

Now that we’ve provided the simplest explanation of each picking, it’s important to understand who utilizes each picking, the challenges those businesses face, and how to solve them. Let's take a deeper dive into some of the top challenges each picking operations face and how to solve them by maximizing space with dynamic high-density storage!

Where is Each Picking Used?

Each picking operations are typically employed in warehouses, fulfillment centers, and retail operations focused on delivering products directly to customers. Depending on the type of business and SKUs being stored, each picking can comprise a large portion or even 100% of an operation's picks. In other words, optimizing each picking is something almost every order fulfillment operation today needs to care about.

Big box retailers utilize each picking to fulfill online orders, including those for in-store pickup. Each picking is also crucial for fresh grocery delivery services where grocery orders are picked, prepared, and shipped directly to customers’ homes. Third-party logistics providers (3PLs) typically fulfill orders for a wide variety of eCommerce businesses, so their order picking operations are primarily made of each picks as well.

Each Picking Challenges

In many warehouses and distribution centers, each picks are stored inefficiently, stretching pick times, consuming valuable floor space, and costing thousands in lost productivity.

Some of the major factors contributing to these inefficiencies are:

- SKU proliferation

- Running out of space

- Poor SKU accessibility and visibility

- Rising labor costs

- Disorganized order picking processes resulting in errors and mispicks

Because of the lower revenue and higher labor costs generated by each picking compared to other types of order picking methods like case picking, for example, companies need to ensure their processes are optimized for fast, easy, and accurate order fulfillment. Does this sound like a lot? Well, it is! But we’re here to tell you that, despite a growing number of challenges, there is actually one magic bullet solution that can help you start solving all of these problems. If you’re looking to optimize each picking, start with space utilization!

Discover a high-density storage solution and get the Ultimate Order Fulfillment Checklist! Download the Meet SpeedCell Guide.

How to Improve Each Picking

The best way to ensure you run a well-optimized each picking operation is to start with space utilization. But what does this mean? Simply put, one of the major issues all operations face is poor use of space. For example, if you’re picking thousands of SKUs from open cases stored on pallets on the floor, your each picking operation is likely spread out across a large area of your warehouse. Workers have to travel a great distance to find these SKUs. They have to bend over and rifle through an open box to pick products, hoping it is the correct box because, chances are, it’s not well-labeled or it's mislabeled.

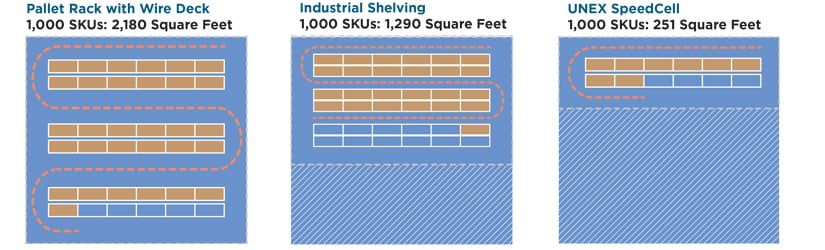

Storing those same SKUs in static industrial shelving like steel or rivet shelving, or on wire decking in pallet rack is a slight improvement because you are making better use of your vertical space. By getting SKUs up off the floor and onto shelves, you’ll likely be able to condense your each picking footprint a bit. This approach will allow you to better organize your SKUs as well. However, you still wouldn’t be taking full advantage of the entire width and depth of your racks or shelves - there is still more space to save! That’s where dynamic storage solutions come in…

Each Picking and the Dynamic High-Density Storage Difference

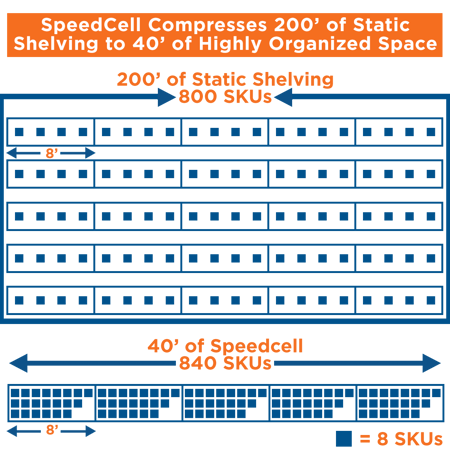

A dynamic high-density storage solution like UNEX SpeedCell can compress 200’ of rack or shelving into 40’ of highly organized space, resulting in more pick facings and greater SKU density. Storing your SKUs in a very dense storage system will significantly condense the overall footprint of your each picking operation. It will also lead to better organization with clearly labeled pick facings. A smaller footprint means less travel time for workers. More organized SKUs, improved visibility, and labeling will reduce search time. All of this results in faster picks and restocking. So it is easy to see the benefits of this domino effect; focusing on increasing space utilization for your each picks results in enormous cost savings for your business. And SpeedCell is the perfect solution to help you make it happen!

SpeedCell for Each Picking

SpeedCell helps businesses tackle each picking challenges by providing an extremely dense, moveable storage system that allows full access to every square inch of your pallet racking.

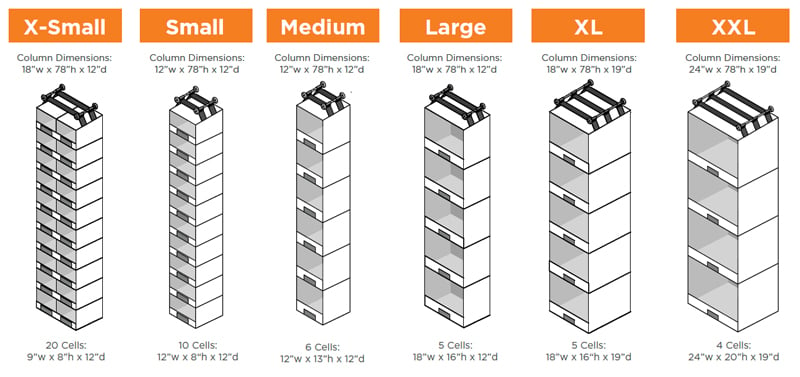

SpeedCell is offered in 6 standard sizes ranging from XS to XXL to accommodate a wide variety of products. SpeedCell columns are designed to hold up to 240 lbs., which means you can fit quite a few SKUs in this system!

Each shelf or “cell” has a lip designed to prevent items from spilling out, even when in motion. With SpeedCell, your SKUs are out of the “dead zone” and into the “golden zone” - not too low, not too high, and never too far out of reach since the moveable shelving allows deep access to your entire bay. Our XS column size comes with a collapsible divider, offering even more versatility for storing your each picks. With the divider up, you have many extra-small-sized cells that are perfect for storing your smallest items or your slower-moving SKUs that get picked infrequently. With the divider down, you have a set of medium-sized cells to store slightly larger products or just a higher quantity of each SKU.

With SpeedCell, operations can increase storage density by up to 60% and reduce labor costs by up to 40%. Bottom line: SpeedCell saves you money.

Optimize Your Each Picking Operations with UNEX

UNEX designs optimized each picking solutions like SpeedCell with three goals in mind: increase pick rates, decrease mispicks, and improve ergonomics at the point of pick. SpeedCell can be customized to fit a wide variety of rack structures and can be used in conjunction with a number of other UNEX solutions like carton flow, gravity conveyors, and SpeedCartt - SpeedCell on wheels! Connect with our product experts to learn how UNEX SpeedCell can help you increase space utilization and boost productivity in your each picking operation.